In one of the scenes in the Hollywood movie M3GAN, a CEO is frustrated that a competitor has been able to replicate a toy manufactured by their company. He is asking the engineers and designers to enhance the functionalities of the toy to stay ahead of the curve. The lead engineer with a more innovative idea states: “The only way to stay ahead is to generate innovation that is very difficult to replicate.”

I keep on throwing the buzzword “differentiating capability” out there. This dialogue in the movie captures exactly its definition.

Smart manufacturing capabilities are currently on an exciting milestone in its evolution journey. The technology to power it should ideally be no longer considered emerging. There are new products, platforms, and solutions emerging every day. Almost all major manufacturing companies have made some foray into this domain. Yet, very few have mastered it.

The automation and software implementation part has been completed by many. That is the part that opens the gate to the most valuable resource. Access to real-time data. And companies that will be able to build differentiating capabilities will be leveraging this data beyond measuring legacy KPIs.

When leveraging smart manufacturing data, we are fixated on predictive maintenance. And we have been fixated on it for years now. If you have not implemented predictive maintenance capability in your smart manufacturing setup, you are behind on the technology curve. For those at par, it is time to build capabilities that will widen the gap between leaders and laggards.

Analytics is the lever that can help you develop that differentiating capability. In this article, we will discuss an example of how analytics can be leveraged to run an optimized manufacturing network, where the metaheuristics approach can help run an optimized manufacturing network at the most granular level.

This idea originated while reading the book “Metaheuristics for Logistics” by Laurent Deroussi, specifically chapter 9 (Hybridization and Coupling) and chapter 10 (Flexible Manufacturing Systems).

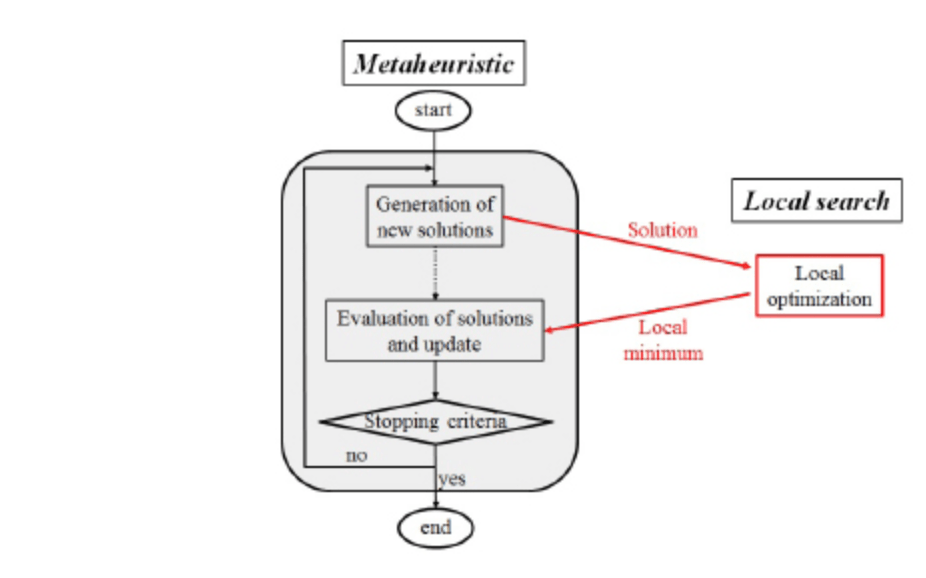

Metaheuristics is a higher-level procedure designed to find, generate, tune, or select a heuristic that may provide a sufficiently good solution to an optimization problem or a machine learning problem, especially with incomplete or imperfect information or limited computation capacity.

The author introduces the Principle of the hybridization “metaheuristic/local search,” shown in the figure (reproduced from the book) below.

The example in the illustration focuses on the supply chain and uses a specific scenario of optimization and simulation coupling. But the approach can be extrapolated to many scenarios, and yes- Generative AI can turbocharge this approach. The author leverages this approach in another chapter to optimize a flexible manufacturing setup.

With some enhancements, this capability can be integrated into a smart manufacturing setup. Leading smart manufacturing platforms capture all the data that you would need. And then, this can be extrapolated to perform a network-wide optimization in manufacturing networks where the network has been designed to fulfill demands across regions.

The coupling suggested by the author is not carved in stone to be limited to 1:1. The way I visualize it, you can leverage results from one coupling to “couple” with another model. Eventually, it mimics the “portfolio of models” theory I have proposed in many articles. Each model performs a specific sk, interfaces with other models (s) to leverage their output as input data )when needed), and creates an overall optimized analytics ecosystem.

And this is what will build a truly smart manufacturing setup. But it will still be localized.

The coupling approach can then be extended to a “couple” of multiple manufacturing locations (assuming they will all be on the same smart manufacturing platform powered by the cloud). And this will help you build a truly optimized manufacturing network powered by smart manufacturing and analytics. And every technology you need for this to happen already exists. You may have already made the most significant investments in cloud and smart manufacturing platforms. Building this capability requires a skilled workforce but no significant technology investment.

This may not be real-time, though, and this is where deep learning can help. Many of the metaheuristic swarm intelligence algorithms that I have been sharing in a series of articles recently, can be leveraged productively only if coupled with deep learning. As I have highlighted numerous times, optimization models or simulation models’ output data can be used to train deep learning models, and this is no different. You can train a deep learning model on the hybridization and coupling approach suggested.