We are all probably shocked by the Baltimore bridge collapse tragedy. For those not aware, a container ship, Dali, lost power half an hour after it started its 27-day journey to Sri Lanka and ended up colliding with one of the pillars of the bridge, leading to the collapse. Six precious lives were lost.

The theory that investigators are currently pursuing is that dirty fuel led to Dali’s power failure. While such tragedies definitely make you mourn those who were impacted, we should also adopt a thought process where we envision how we can leverage the capabilities in technology that humanity has developed to use so that we can eliminate such root causes.

As I consistently highlight, we have developed some really powerful capabilities that have not yet translated into real-world applications. When I observe the world around me, processes around me, or read about developments and incidences (like this one), I see opportunities to put the capabilities that we currently have (not futuristic) to good use to solve issues both in industrial as well as social context. The need is to channelize the hype in a way so that we can bridge the gap between tech capabilities and applied usage.

An Edge AI solution could have helped in this scenario. In fact, if dirty fuel turns out to be an issue, regulators should make it mandatory for shippers to have this type of technology variation installed.

There are two ways to determine the quality of gasoline (or diesel). One is in its liquid state. In the illustration below, I have used a simple diagram to highlight how Edge AI solutions can help detect fuel issues in near real-time, thereby helping avoid disasters like this. None of this is futuristic. What is lacking is willpower, not technology.

A good aspect of Edge AI applications like these is that they can be supported by an infrastructure that exists on the ship and, hence, will not be hardware-constrained. What is the time-consuming part here is the algorithm training. But based on my analysis of the types of sensors available that can collect data on fluids, there will be plenty of data available to train this type of algorithm, with a fairly high level of accuracy.

Now let us look at the other possible solution.

It is evident that standard measures like pre-inspection of fuel quality failed, leading to dirty fuel getting into the ship’s system. The other approach, which can be useful for various other reasons as well, is to analyze the fumes generated.

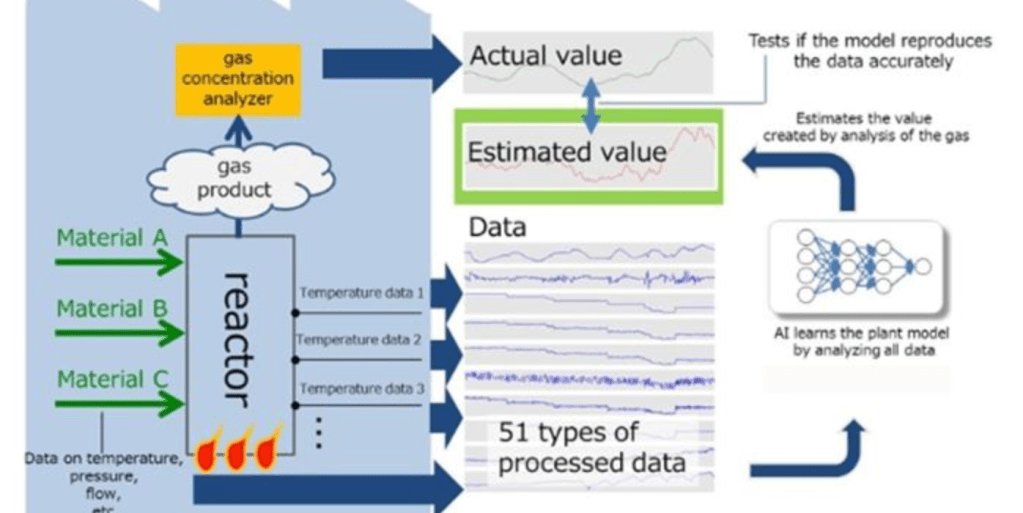

If you are unaware, deep learning-based solutions to evaluate the quality of gas (not gasoline) in near real-time already exist. I am unsure if these solutions have been commercialized yet, but I came across one last year. Since I bookmark articles I find interesting, I was able to dig this specific article out. This article, Predicting Gas Quality with Deep Learning Techniques During Chemical Production, summarizes a solution that can predict gas quality by analyzing the fumes. Note that the term “gas” in this context is not gasoline. But the solution is still relevant.

The architecture, as suggested in the article, is below. It is from a chemical plant context but just by visualizing the components, you can say that it is not difficult to extrapolate this to our specific situation.

Let us understand why this solution is helpful in our context. If somehow the AI solutions to track quality during the liquid stage of the product, highlighted above, fail, extrapolation of the solution above can help us analyze the fumes being generated to flag if the fuel being injected is dirty. I assume that ship’s engines are run for a certain duration before it leaves the harbor. An edge AI solution can analyze these fumes, while the ship is still docked, and highlight discrepancies.

I believe technology can address a majority of issues we are facing today. All we need to do is take a step back from all the hype and understand how we can leverage the hype for good.