This article is the third part of a three-part article series. In the first part we discussed the drawbacks of current process of VSM design. In this second part of the article, we explored what value stream mapping is about, the critical aspects that need to be captured, and how process mining forms the foundation for many digital VSM tools. In the third and final part, we will explore shortcomings in the process mining approach and understand how AI can help address those shortcomings.

To begin our exploration, let us reproduce this figure from the second part of the article.

As you can see in the illustration, the current approach fares well in terms of capturing the current state, specifically process discovery. Process analysis and re-engineering, from a manufacturing VSM perspective, are the areas where current solutions run into bottlenecks.

Possibilities and challenges

One key aspect to remember is that value stream mapping goes beyond creating process maps with data. Specifically, there are both quantitative and qualititative aspects involved. Let us explore an example of a quantitative aspect of VSM that can be easily automated- synchronizing the flow. This has been a challenge in performing VSM manually, as manually simulating scenarios to understand which specific scenario will yield synchronized flow, is very challenging.

With the data available to a process mining solution (if the solution has been designed properly), we can evaluate the current state of the flow and simulate a takt-based synchronized flow.

Takt time helps synchronize the production system so that there is a flow. But a continuous flow is not always realistically possible. That is where you build small inventory batches on the floor, known as supermarkets in lean parlance. The goal is to control the flow of production by linking stations to their downstream customers through a supermarket-based pull system. That is another area where, either through process mining solution, or by tapping into the data and calculating the supermarket parts inventory quantity.

But let us take a look at an example that is challenging to automate, leveraging current approaches to automation and analytics. The example involves identifying which elements are value-adding vs. non-value-adding.

The official definition is that non-value added activity is an activity that customer would rather not pay for. The fact is, the customer does not give a sh*t anymore. But for the manufacturer, it is definitely worth eliminating or minimizing non-value add activities, to reduce production costs. However, it is challenging to categorize from the data points that process mining solutions typically tap into.

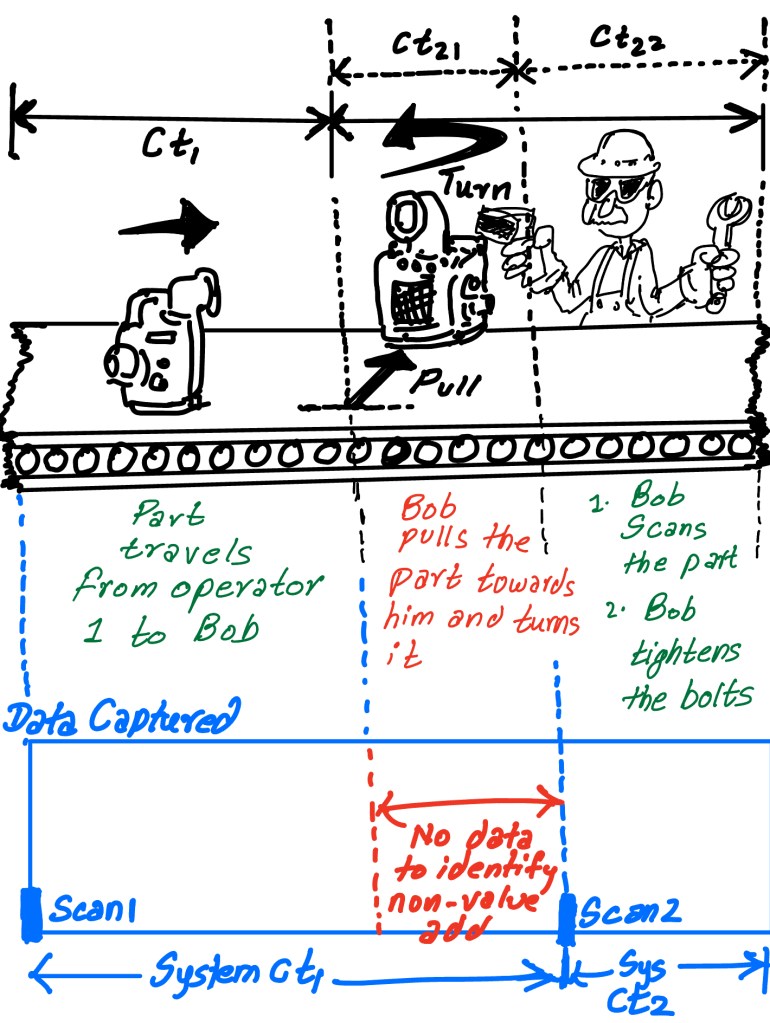

Let us say there are three movements of the semi-finished good during a segment of the cycle time as shown in the figure below.

Typically, that movement will be aggregated due to a certain scan or log in the system. The data captured has no visibility into those three movements. The system data has tow sets of time only, thereby embedding the non-value added time inside System ct2. This is the data the process mining solution will capture as well. There is not visibility for the process mining solution into the actual ct21, shown in the figure above. That is the non-value added time.

And this is where Generative AI can come into play !

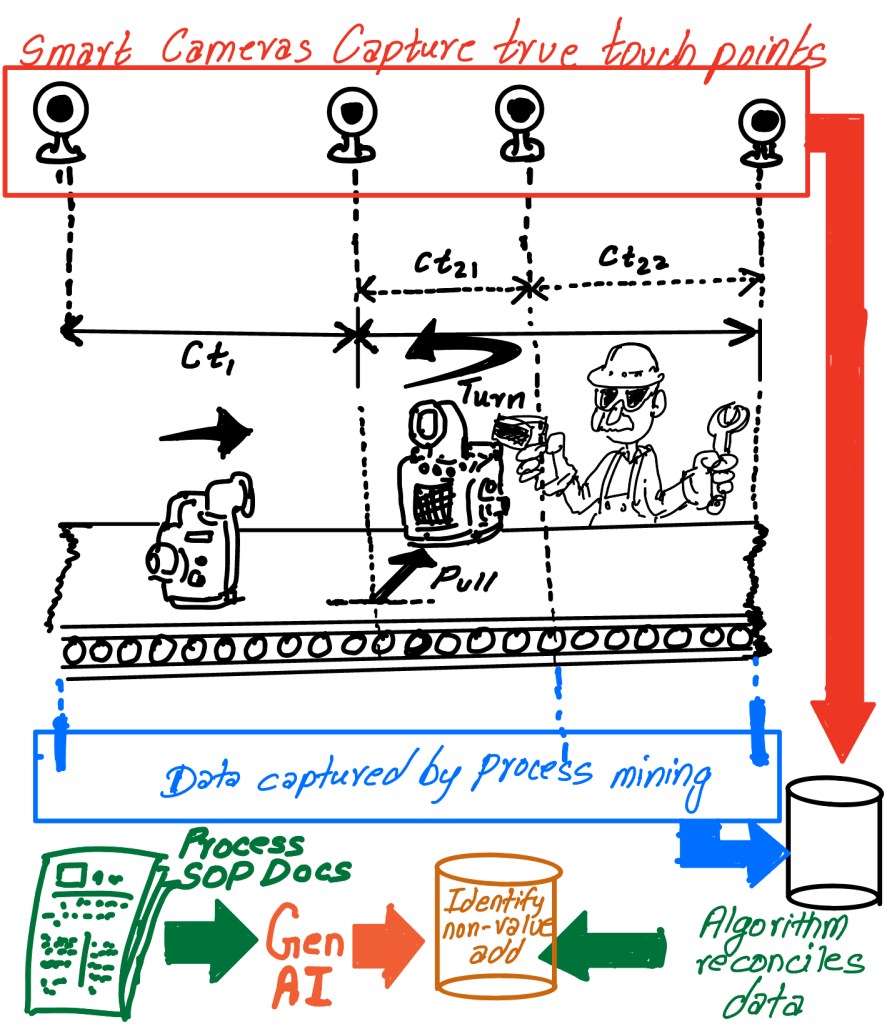

It may be possible to automate all the envisioned elements of the VSM process, coupled with additional technologies like Generative AI. The illustration below shows how we can incorporate the element of value-added analysis discussed before into an automated VSM solution.

The example above is just one example of how bottlenecks with the current process can be tackled leveraging Edge AI and Gen AI. The fact is, with the technologies we currently have, we can indeed build an automated VSM solution. But the current solutions available are not true VSM solution.

The beauty of building such smart and truly automated VSM solutions is that they will also address the learning and propagation aspects as well. Rather than a handful of “experts” understanding what lean is all about and what VSM is, Gen AI can proactively engage everyone on the floor, to understand the impact of what they do on syncing the manufacturing flow, and ensuring a lean world class manufacturing process. We will explore this in a separate article.