This article is the second part of a three-part article series. In the first part we discussed the drawbacks of current process of VSM design.In this second part of the article, we will understand what value stream mapping is about, the critical aspects that need to be captured, and how process mining forms the foundation for many digital VSM tools.

Then in the third and final part, we will explore shortcomings in the process mining approach and understand how AI can help address those shortcomings.

Digital VSM solutions was the topic of discussion in this morning’s “Monday Motivation” episode as well. You can watch the episode here:

Before we jump into digital VSM solutions, let us review some guidelines for value stream mapping, suggested by the Lean Enterprise Institute. You can find them on the institute’s website. The reason we want to review these is because these guidelines will help us highlight limitations with current digital VSM processes.

Value stream mapping guidelines (reproduced from Lean.Org)

Guideline #1: Produce to your takt time

“Takt time” is how often you should produce one part or product based on the rate of sales. Consequently, it is a proxy for customer demand.

Guideline #2: Develop continuous flow wherever possible

Continuous flow refers to producing one piece at a time. Operators immediately pass each piece to the next process step without stagnation in between.

Guideline #3: Use supermarkets to control production where continuous flow does not extend upstream

There are often spots in the value stream where continuous flow is not possible and batching is necessary. Resist the temptation to schedule these process via an independent scheduling function. Instead, control their production by linking them to their downstream customers through a supermarket-based pull system.

Guideline #4: Try to send the customer schedule only to one production process

By using supermarket pull systems, you will typically need to schedule only one point in the value stream. This point is called the pacemaker process. This is because how you control production at this process sets the pace of production for all upstream processes.

Guideline #5: Distribute the production of different products evenly over time at the pacemaker process (level the production mix)

Most assembly departments probably find it easier to schedule long runs of one product type and avoid changeovers. However, this creates serious problems for the rest of the value stream and customers, such as:

- Increases the lead time from order to delivery

- Swells in-process inventories

The more you level the product mix (aka “heijunka”) at the pacemaker process, the more quickly you will be able to respond to different customer requirements while holding less inventory.

Guideline #6: Create an “initial pull” by releasing and withdrawing small, consistent increments of work at the pacemaker process (level the production volume)

Too many companies release large batches of work to the shop floor processes, which causes several problems, such as:

- There is no sense of “takt” or pull from the customer to which the value stream can respond.

- Responding to changes in customer demand becomes very complicated.

- The state of production becomes difficult to monitor.

Establishing a consistent, level production pace creates a predictable production flow. Consequently, this allows management to see problems more easily and take corrective action faster.

Current methodologies of Digital VSM

Majority of digital VSM solutions and approaches use process mining as foundation. It is therefore important to overview the capabilities in a best-of-breed process mining solution. Process mining capabilities can be generalized into the following three key stages:

Process Discovery: This capability pertains to recreating the process leveraging data captured. A key point to note here is that majority of process mining solutions currently leverage data from MES and ERP systems, vs tapping into sensor data directly. But since they are at this point rarely used for real-time applications, the current approach works fine for the discovery stage.

Process Analysis: This capability is around process control. In this capability, the solution can compare the process digital model, with the recreated model in the discovery stage. Deviations are flagged, and if within the realm and capability of the solution, the drivers behind deviations may be identified.

Process re-engineering: This is the advanced capability where the solution should aim to suggest a future state process, based on findings from the process analysis stage.

Key steps in VSM

Now let us jump into the value stream mapping world again, and understand, at a high-level, what are the two critical steps in a value stream mapping exercise.

Value stream analysis

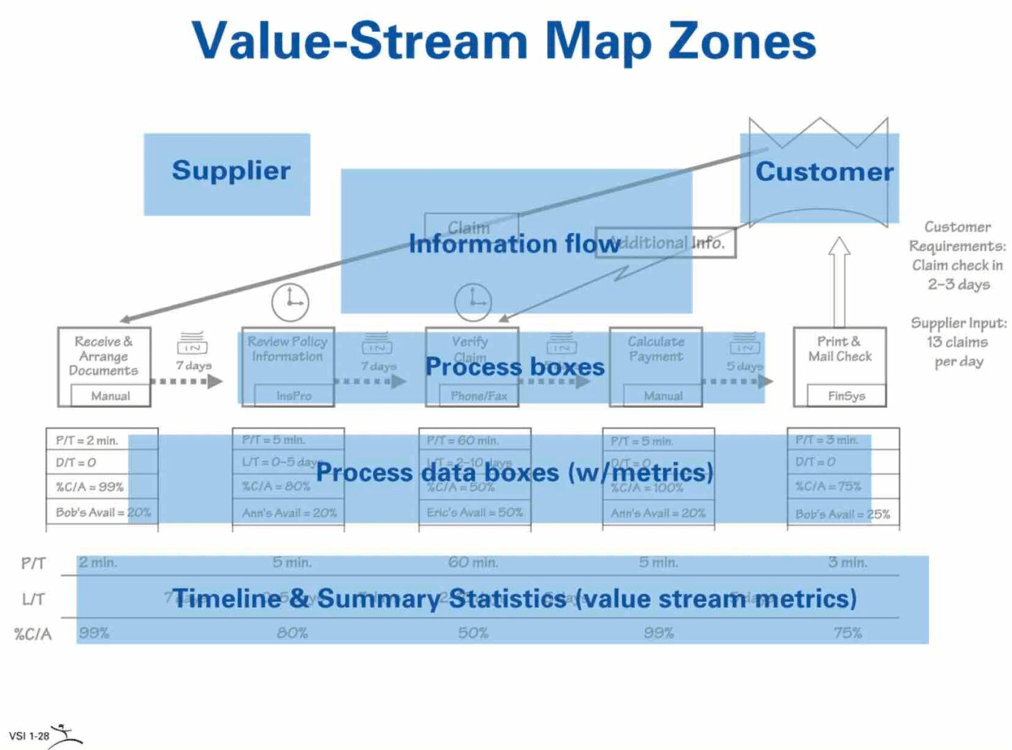

The illustration from Lean Enterprise Institute shows the key pieces of information captured in the value stream analysis process:

Source: Lean.Org

Examples of Key pieces of information captured are:

Information flow — tells each process what to make or do next and when to do it.

Process data

- Cycle Time (C/T)

- Lead time (L/T)

- Uptime

- Changeover time (C/O)

- % Complete and accurate (%C/A)

- Availability

Value stream design

One aspect that you may have observed from the value stream map above is that, unlike some other process maps you have seen, value stream maps are kind of high-level. For example, document receipt and filing can have a detailed process map of its own. But in a VSM, it is represented by a higher level process box

Once you have the current state data captured through the analysis, you start designing your VSM. However, as you can assume, these two steps are not mutually exclusive and have some elements of being iterative. For example, to capture data, you need a high-level idea of what you want to map, which elements will be aggregated as one single high-level process, and aspects like that.

How process mining helps digitize VSM

If you look at the process flows and information data, and you are familiar with the capabilities of process mining solutions, it should not be difficult to understand why process mining solutions can be a great foundation for value stream mapping. The illustration below captures the alignment between process mining capabilities and value stream mapping activities. The illustration leverages the example of production processes.

As you can see tasks like identification of product families, and capturing the current state process flow and associated data can be addressed by the discovery stage of the process. So essentially, the process discovery capability can provide most of the information needed to build a current state VSM. But the key question is, can it provide all the information needed to build a current state VSM?

Imagine that you are the plant manager of a manufacturing plant that currently caters to one large customer only. If you were to design a current state VSM, will the data from a process discovery tool sufficient? The answer should be No.

In the third and final part of this article series, publishing on 03/07, we will discuss the gaps that process mining based solutions may leave, and then explore how AI can help fill those gaps.