This article is the second part of a series of three articles. In the first part, we discussed the core issues that led to Boeing’s challenges and categorized them into manufacturing and supply chain categories. In the second part, we explored how AI-enabled solutions can help alleviate issues like incorrectly drilled holes in manufacturing. The third and final part will examine how AI-enabled vision-based quality solutions could have helped detect the defects.

The “quality check miss” across the supply chain

As highlighted in the first part of the article, the roles that were defined in the supply chain of these aircrafts, for our example scenario of exit doors, were:

- Spirit was responsible for constructing the exit doors, both the usable ones and the plugged ones. AND doing the initial quality inspection

- Boeing was meant to do quality-control checks on pressurization and seals on its finished planes.

- FAA was meant to double-check each 737 on its way out the door.

All three entities missed the quality check, and the aircraft ended up being operational with the defect. I am unfamiliar with the manufacturing and quality check processes at Spirit and the quality check processes at Boeing and FAA, but smart, vision-based quality checks could have helped detect these issues.

In my “Monday Motivation” video this morning, I highlighted some off-the-shelf, vision based solutions that are available in the market. You can watch the episode here:

It is not necessary that an off-the-shelf solution can help detect unique structural nuances in Boeing’s manufacturing processes. But building a custom solution is relatively easy these days. Let us explore the key components of existing solutions and how they work.

AI-enabled vision based quality inspection

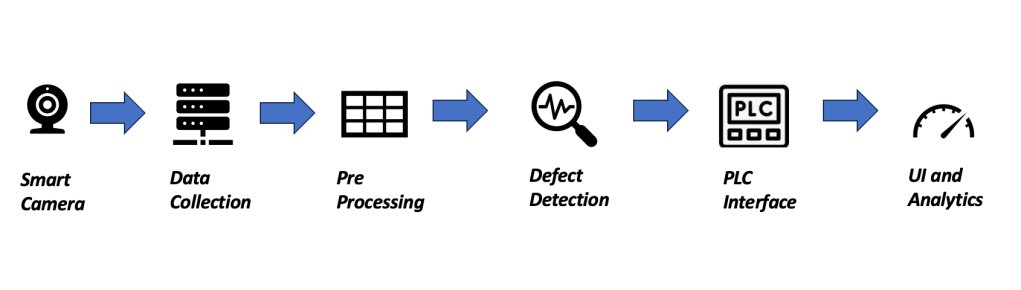

As highlighted in this week’s “Monday Motivation” episode, at a high level, the process flow of a vision-based, AI-enabled quality inspection solution is similar to Figure 1.

Figure 1: Process flow of Vision-based, AI-enabled quality inspection solutions

Let us understand what these steps are:

Acquisition and pre-processing

Once the data ingest of source images occurs, the pre-processing step performs the data validation. This sanity check process involves checking file integrity and detecting annotations and labels attached to the uploaded images.

Defect Detection and Status

This is where AI algorithms come into play. Deep learning algorithms are typically leveraged for vision-based quality inspection. An examplesof types of algorithms that are leveraged is Generative Adversarial Network. GANs focus on automatically discovering and learning the regularities or patterns in input data. We will overview GANs and their relevance to visual quality inspection in a separate article on 01/23.

PLC Interface

The PLC interface uses digital signals to interact with the external hardware, including programmable logic controllers (PLC). This interface is designed to retain the security and reliability of the process while ensuring communication efficiency within the solution setup.

Interactive User Interface

This is the interface to interact with the overall solution. From changing requirements and parameters, to getting KPIs and analytics pertaining to the quality process, the interface provides users with a powerful tool to interact with the solution.

And if an off-the-shelf solution does not fit your needs, you can build and train your solution with all the above components.

Advantages of vision-based quality inspection solutions

Let us explore the advantages this solution could have brought to Boeing. These are generic advantages, though, that we will explore in this specific scenario. As you will notice, these solutions not only help mitigate defects but also the impact of that mitigation goes beyond compliance and safety. Remember that there are other benefits as well, like reduced costs. They are important but not the primary ones in our specific context.

Increased process effficiency and productivity

Due to their capability to “learn” from data over time, the level of complexity these solutions can detect increases with time, including those on which humans may not have been trained. Whether built or bought, these solutions can detect complex and even the most minuscule defects across the assembly process on various surfaces. Hence, significantly less manual work is needed, which increases process efficiency and productivity. In Boeing’s context, the inspection totally missed the defects. The resulting situation has led to processes and work that these solutions could have easily avoided.

Increased Accuracy

Detecting the defects early on could have helped Boeing avoid all the kabuki dance it now has to do. Not only can these models initially do a better job than humans, but continuous training of these models with new categories of defect data continuously improves the accuracy of predictions. The result is the capability to avoid costly product recalls.

Compliance to Regulatory mandates

This is a no-brainer for this case study. These solutions could have helped Boeing ensure compliance with FAA regulations and could have also helped the FAA avoid all the embarrassment and reactionary fiasco.

Alleviate Human Health & Safety Concerns

Another no-brainer. The risk that passengers on that Alaska Airlines flight faced could have been avoided.