This article is the second part of a series of three articles. In the first part, we discussed the core issues that led to Boeing’s challenges. We categorized the issues into manufacturing and supply chain categories. In this part, we will explore how AI-enabled solutions can help alleviate issues like incorrectly drilled holes in manufacturing.

Smart Manufacturing: AI-enabled monitoring of hole machining operations

When I first read about the Boeing issue and that one of the drivers was attributed to a drilling issue, a product that I had come across immediately came to my mind. When we relocated, I had to repurchase many of my tools. While searching for drills, I came across a drill that claimed it was a “smart” drill powered by AI.

Upon further research, I realized that though the feature was indeed “smart,” it wasn’t enabled by what I consider AI. Then, I realized that AI in the description stood for “Advanced intelligence.” But that did make me curious, so I researched applications of AI-enabled drilling in an industrial context, with little anticipation that I would. find a real-life use case so soon.

The gist is that the remedy, or the exact AI-enabled technology solution, already exists. Innovative drilling is a thing, and there is even an annual smart drilling conference that takes place every year. Both as industrial products as well as expansion of those products in academic papers like these:

Innovative Smart Drilling with Critical Event Detection and Material Classification

Augmented-reality-assisted timber drilling with smart retrofitted tools

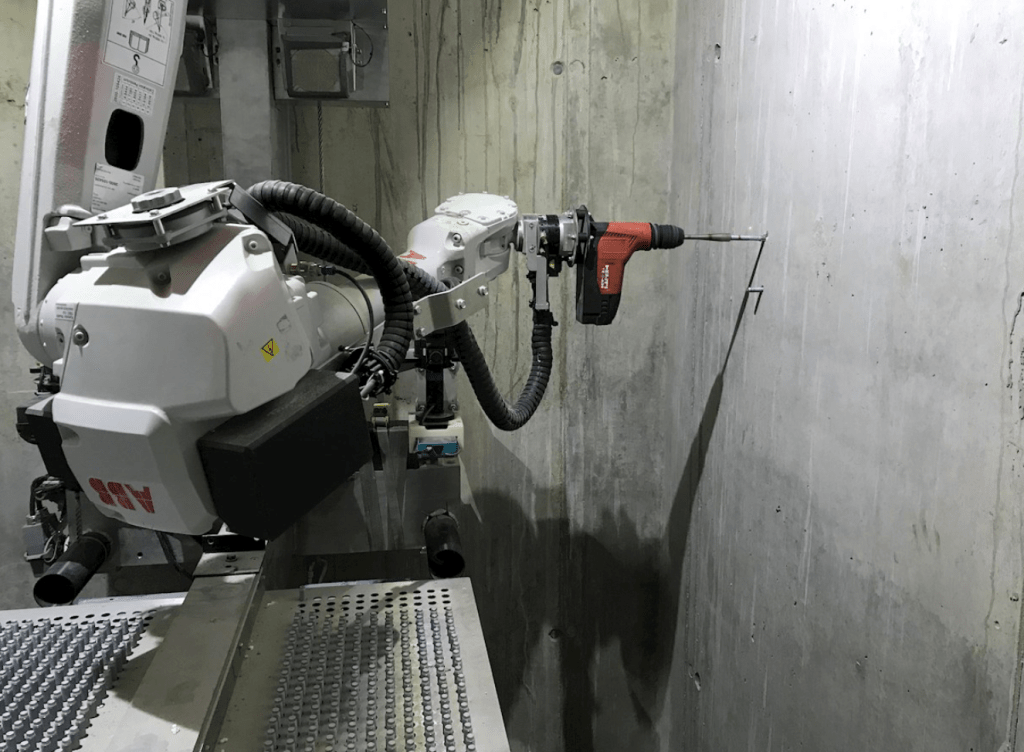

The mechanism is simple (to understand). Sensors with smart vision can help drill exact and precise holes. You can even automate the entire manual component of the drilling process, as seen in the figure below. This solution from ABB has been implemented by Schindler.

So when I read about the drilling defects, I did some Aerospace specific research on smart drilling. I wanted to understand if these solutions are being leveraged in Aerospace manufacturing or not. The article, A.I. Fuels Aerospace Manufacturing Automation, on the Society of Manufacturing Engineers website specifically mentions drilling operations.

Ironically, the article has a quote from a Boeing engineer: “We learned a lot about why; (it’s because of) the way the robots work in terms of their accuracy and their stiffness,” explained Freeman, senior technical fellow, Boeing Research & Technology (Charleston, S.C.), Boeing Co. “Then, through that, we figured out how to overcome those challenges. And now, I don’t know of an aerospace company that doesn’t have robots drilling on aircraft.” So did Spirit not have them? And if it did, it becomes a people and processes problem, vs a lack of technology issue.

The gist is that AI-enabled solutions already exist to address the drilling issue that led to the failures. While Boeing may decide not to reintegrate this operation into its fold, it can probably help Spirit modernize its manufacturing process to become a truly smart manufacturing operation. If Spirit does not already have smart manufacturing capabilities, it may be time to transition. If they already have some capabilities in this area, now may be the time to modernize.

In the third and final part, we will explore how AI-enabled solutions can help with the supply chain issue of missing quality issues. The final part will be published on 01/22.