This article is a part of a series of articles. Links to previous parts can be found in the appendix section of the article.

Grasshopper Swarm Optimization

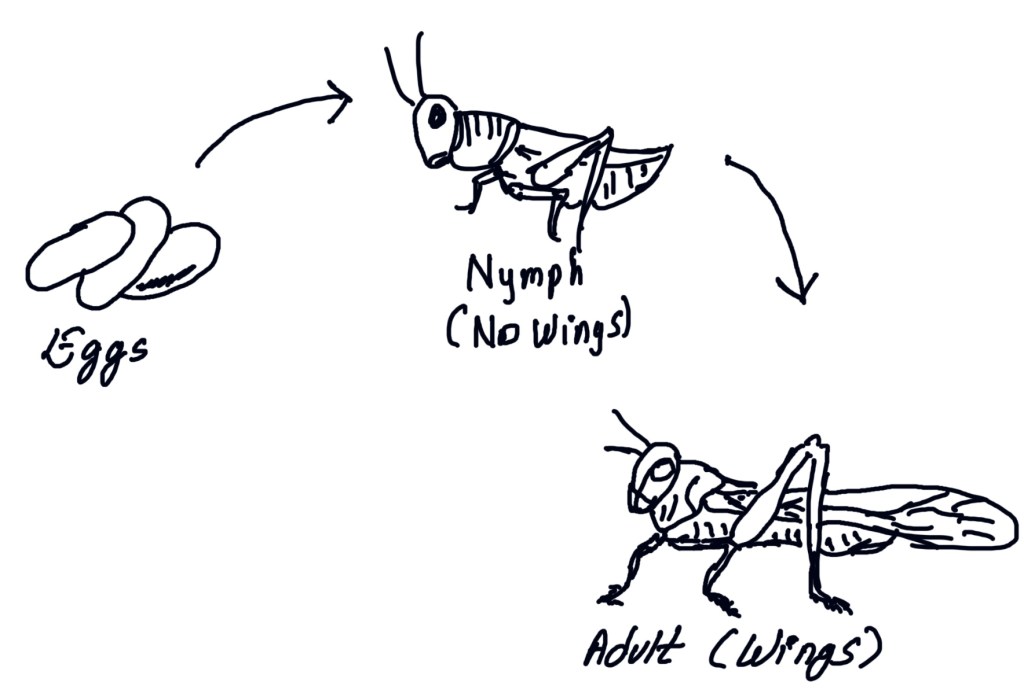

You need to quickly overview a typical grasshopper life cycle to better understand the behavior based on which Grasshopper swarm optimization works. As shown in Figure 1, the life cycle is three stages: egg, nymph, and adult.

Figure 1: Grasshopper Life Cycle

Life cycle

- Egg: This stage lasts a few weeks. Under the right circumstances, eggs hatch to become the first instar Nymph

- Nymph: Nymphs mature in stages, with each instar beginning their journey to become an adult. The nymph has to go through six stages to become an adult and in the first stage, they do not have any wings. However, the wing-buds grow in size at each stage. Because of the lack of full grown wings, the swarm moves slowly

- Adulthood: In this stage, wings are expanded and fully functional after the final instar stage. In this stage they form aerial swarms and move fast to a large-scale region

Swarm Behavior

Now let us explore the swarm behavior, which draws from the lifecycle stages explained above.

- In the nymph phase, the swarm moves slowly because nymphs don’t have wings

- Once the nymphs have wings, the swarm can make quick jumps and long-range moves.

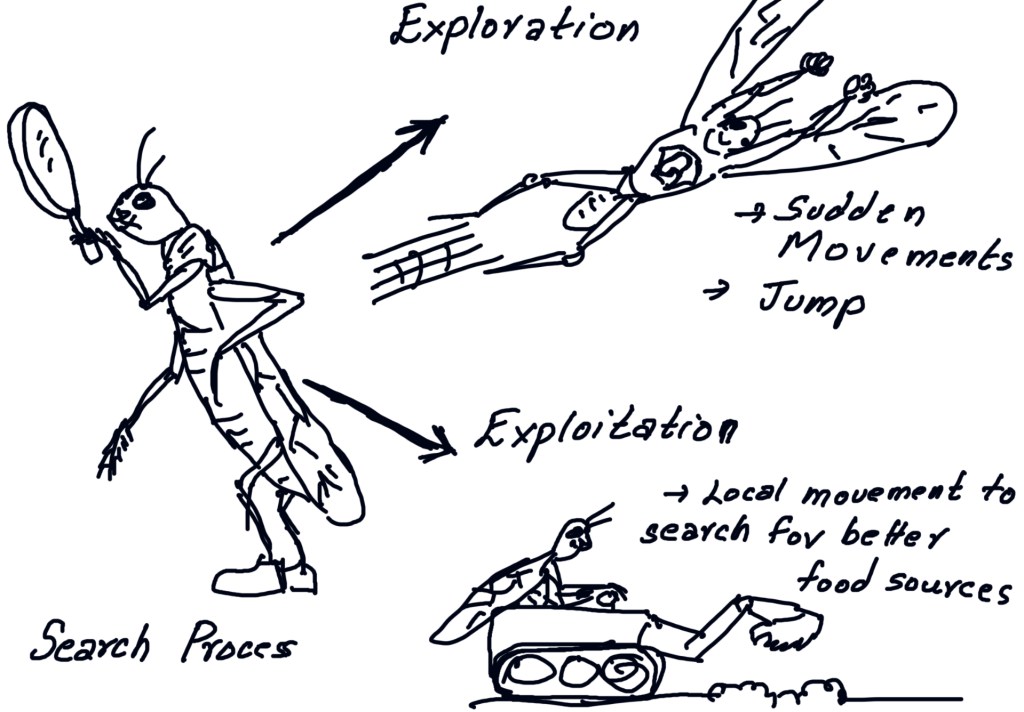

- The swarm searches for food by splitting the process into exploration and exploitation.

Figure 2: Exploration and exploitation

Applications of Grasshopper Swarm Optimization

Applications of grasshopper swarm optimization algorithms are as varied as any other swarm intelligence algorithm. Let us explore few interesting categories with examples.

Scheduling

Scheduling obviously was interesting due to its omnipresent usage in the supply chain, specifically manufacturing. Interestingly, I did find quite a few research papers that suggested leveraging this algorithm for manufacturing job scheduling. However, it might not be worth it to leverage these algorithms in some instances. Some examples of scheduling-related research papers are below.

An improved grasshopper optimization algorithm for task scheduling problems

A Grasshopper Optimization Algorithm for the Flexible Job Shop Scheduling Problem

While one of the papers pertains directly to job shop scheduling, all the scheduling-related work pertaining to swarm intelligence algorithms can be easily extrapolated to the supply chain world. The key is obviously to match the right problem with the right algorithm and to understand that only an optimization-based approach may not be practical when it comes to generating these schedules in real-time.

Noise elimination

While initial review may indicate that this category is primarily focused on the area of digital signal processing, I believe this can be extrtapolated to the world of demand forecasting. Not essentially to forecast but to eliminate noise in the data.

Grasshopper Optimization for Intrusion Detection System

As you may have already visualized after going through the papers, the algorithm can help reduce noise from complex datasets for demand forecasting. Unless I leverage it on a real-data set, I can’t say with certainty how effective it will be or what level of accuracy improvement this can lead to.

Structural design

While this category may seem totally non-useful from a supply chain operations perspective at first glance, it is not. If you go through these papers, you will realize that these algorithms can not only be used to design optimal structures but also to evaluate an existing design. And this “evaluation” aspect can be extrapolated to the supply chain world. More on this coming in a separate article tomorrow (12/12).

The structural weight design method based on the modified grasshopper optimization algorithm

Grasshopper Optimization Algorithm Based Design of Structures

End-to-End optimization

I will share only one paper in this category, but it is beautiful. I am not a mining industry expert, so I am unsure if this has been applied in the real world. Still, this approach can potentially be leveraged in optimizing complex warehousing operations, or, to be more specific, designing optimal warehouse operations flows and layouts.

We will continue our journey of swarm intelligence algorithms in the subsequent article. The article will be published on 12/12.

Appendix

This article is part of a series of articles. Previous parts of this article series can be found here: