When it comes to technology solutions, we are in a buyer’s market. Never before had the buyer had this much flexibility to procure solutions customized to their needs.

The word “procure” here pertains to primarily custom-built solutions or off-the-shelf solutions married with customization.

This situation is a challenge for many off-the-shelf solution providers. Regardless of fancy marketing jargon leveraged for marketing these solutions, like integrated, cloud-native yada yada.

Based on my knowledge of a couple of these solutions, you can develop solutions that do a three times better job with a one-time investment of less than $100K. And these solutions will be open to customization and enhancement at no additional cost. No advancements in technology will make them obsolete. Because you can infuse advances into these solutions with little effort.

The whole quest of Industry 4.0 is not very different. The buyer is the king in this domain as well. Manufacturing is ahead in the game, but opportunities to build smart DCs are still less mature relative to manufacturing.

I recently came across the results of a survey on DC automation. The survey was conducted anonymously, and the managers expressed their candid opinion. Surprisingly, ~ 54% of those managers thought automation had not made their job easier. 18% of them believed it had added additional issues to their bucket list that they had to resolve daily.

Where is the disconnect? On the one hand, automation of warehouses is touted as a solution to all the operational challenges that a conventional DC faces on a day-to-day basis. On the other hand, the actual people managing these warehouses don’t think things are going that way.

In my mind, the driver behind this disconnect does not realize the actual value of an automated DC by providing a finishing touch and converting it into a wise DC. This post will explore the difference between an automated and a smart DC. In subsequent posts, we will explore some critical aspects of a wise DC and how it helps support your operations strategy.

Before we embark on that journey, let us review some fundamental building blocks of an automated DC that are also the foundation of smart DCs.

Basic building blocks of an automated DC – Industrial Processes

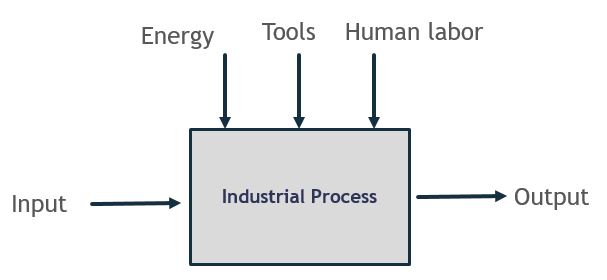

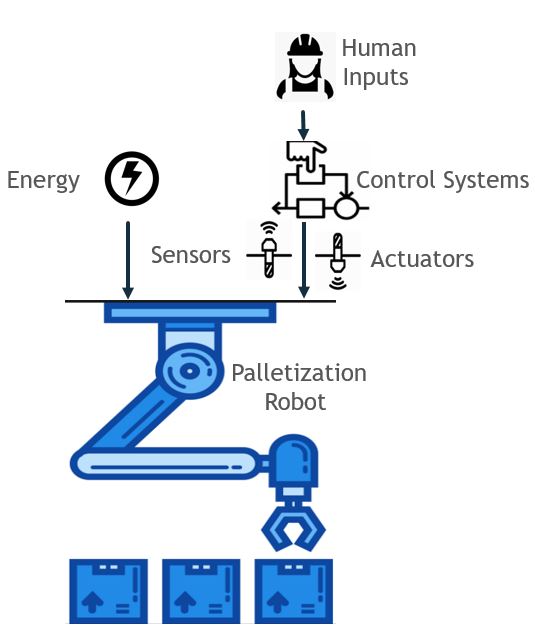

An industrial process can be defined as a set of operations that transform, with a predetermined objective, the properties of one or more materials, types of energy, or information. The industrial process also includes collecting, elaborating, and sharing knowledge along all production phases and steps. A straightforward representation of an Industrial process is illustrated below:

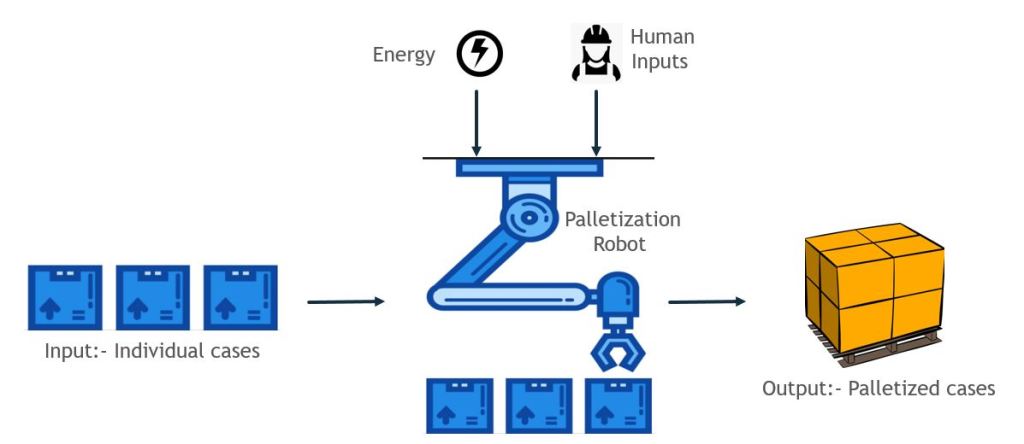

Thinking about industrial processes from an automated DC perspective, a robot station that palletizes cases in a computerized grocery DC is an Industrial process. The cases are the inputs; it consumes electricity, and a human interfaces with its controls. The output is a ready-to-ship pallet.

Note that information is another critical type of Input that an Industrial process (palletizing robot in this case) receives. This information can be in various forms, like the electric voltage, fluid pressure, or any other information that can be coded in sequences of binary values.

Managing the Information aspect- Control Systems, Sensors, and Actuators

Control Systems

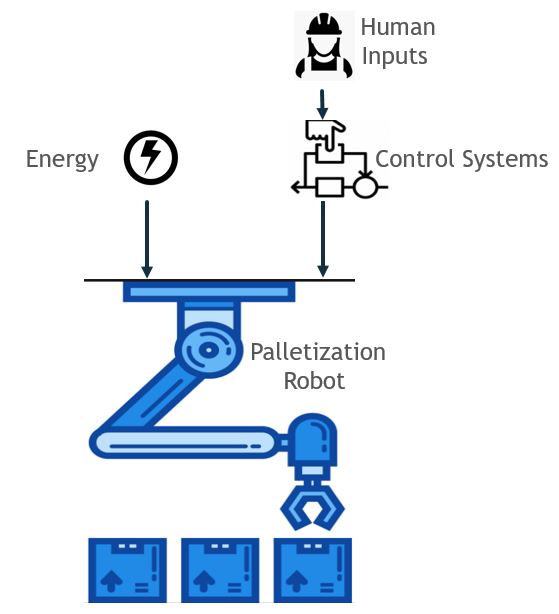

Let us go back to our example of palletization robots again. Typically, Robots in automated DCs are controlled by Control Systems. According to the International Electrotechnical Commission standard definition, an industrial process’s control and measurement system can be described as a set of interconnected devices communicating with each other utilizing one or more communication networks.

To simplify this definition- A control system allows you to exchange information with an Industrial Process. The information exchange is both ways- A Control system sends information to the process and also receives the information.

If you think about this simply, an “On” button on your Washer dashboard is part of a control system. When you push that button, it sends information to the Washer that initiates the washing cycle.

The interface between the control system and the process is missing in the illustration above. It is a device that helps propagate information from control systems to the process.

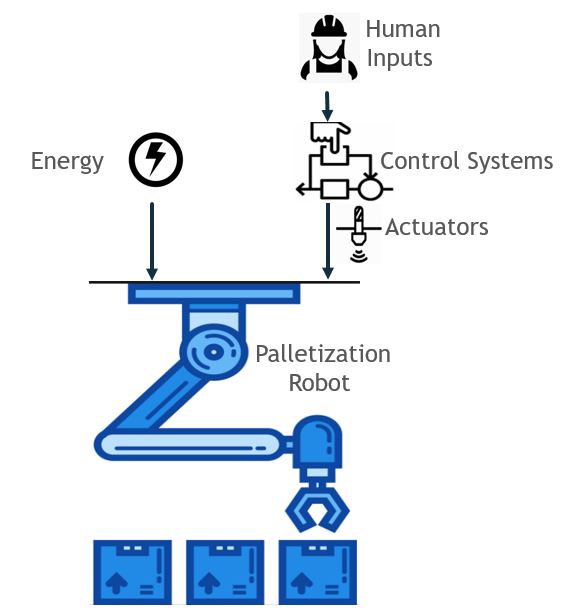

Actuators: Sending the Information to the process

The actuator is a piece of hardware that transforms a command signal into a physical action. It receives a signal as an input in the physical domain of the control device and sends energy as an output in the physical domain of the command variable.

But as you can imagine, this one-way exchange of information, from control systems to process, via actuators, is insufficient. Inputs to the process need to be calibrated based on how the process is behaving given specific information, and a two-way exchange is essential for that calibration. This is where sensors come into play.

Sensors: Receiving the Information from the process

The sensor is a piece of hardware that is similar to an actuator. The flow of information is in a different direction. It transforms the data generated by the process into binary values, which it feeds into the control system. These sensors are generally attached to various equipment in and around the processes (On robots, on and around conveyor belts, etc.) to capture process characteristics and relay the information back to the control system.

Note that sensors and actuators are often also referred to as transducers. Since the sensor and the transducer are often physically within the same component, the two terms are often synonyms. Still, best practices dictate that their usage should be differentiated by terminology.

For a more comprehensive and slightly more technical architecture of smart warehouses, please refer to my this blog post: The IIoT Data Flow in a Distribution Center

The process described so far is automated- but is it smart?

An automated DC scenario

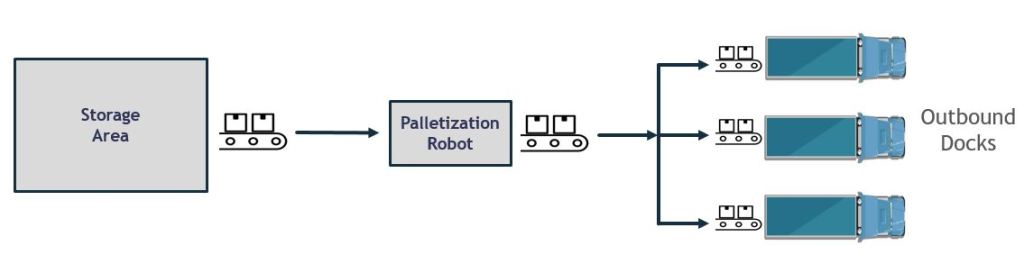

To simplify the example, let us assume this is a DC with only one palletizing robot and three outbound docks. At a high level, the automated pick, pack, and loadprocess in this DC is shown below:

The process is entirely automated. Robots pick up the orders and put them on conveyor belts. These belts carry the cases to the palletization robot. After a pallet is created, the robot places the pallet on a belt that holds the pallet as close to the loading dock as possible. Due to the size of the pallets, the loading is done by forklift operators.

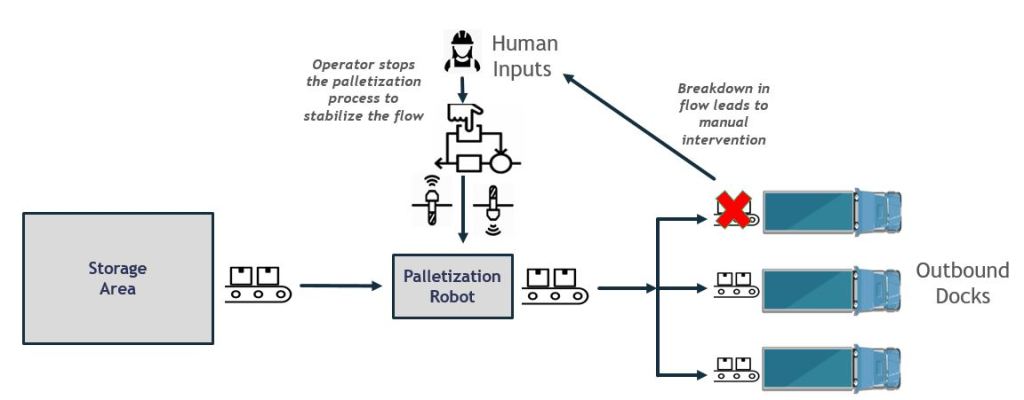

The Bottleneck Scenario

Note that the loading process is manual, where the forklift operators pick up the pallets from loading staging areas and load them on the trailers at the docks. Now let us assume a scenario where one of the operators gets into a minor accident that puts one forklift out of service for a while.

If you know how automated DCs operate, you know that synchronization is the key. In this case, where the loading process has become a bottleneck, an operator generally will shut off the palletization process until the flow stabilizes and syncs again to avoid overflowing the outbound staging area.

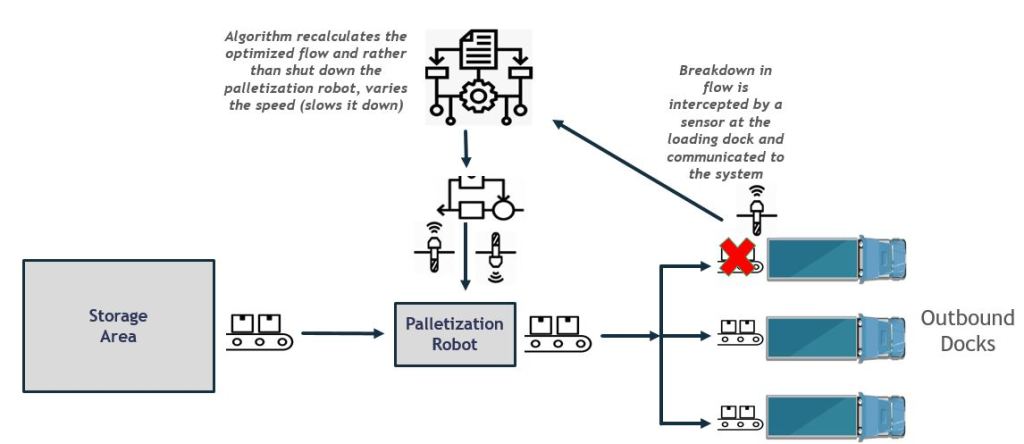

A Smart DC in the bottleneck scenario

Now let us see how a smart DC would handle this. Sensors at the loading docks would monitor the loading rate and ensure the flow is balanced. As soon as the sensors detect that the loading has stopped at one dock, the operating rate/throughput of the palletization robot will be adjusted. The basis of this adjustment will be calculations done by an algorithm. The output value then gets to the robot via the control system and actuator. No human intervention in a smart DC should be needed for a short-term, minor disruption like this.

The algorithms generally interface with a Supervisory Control and Data Acquisition (SCADA) system. SCADA systems are centralized systems that typically control and monitor processes.

The real world is much more complicated

Unfortunately, the real world is much more complicated, and DC processes are very intricate, to the example below. That, however, makes the case for smart DCs stronger. In my next post, I will explain how building the “smart factor” in your DC can help you attain the true ROI of your automation investment. We will also learn how a smart DC can operate with minimum human intervention and what aspects we should allow algorithms to control vs. elements that humans should monitor.