My thoughts on this topic originated when reading about the UWA strike. I will not get into the validity of the grievances that workers have. That is a different topic and one that I best left to experts. I am not an auto industry expert, and neither do I follow the market that closely. So, the gist is I am not qualified to take sides.

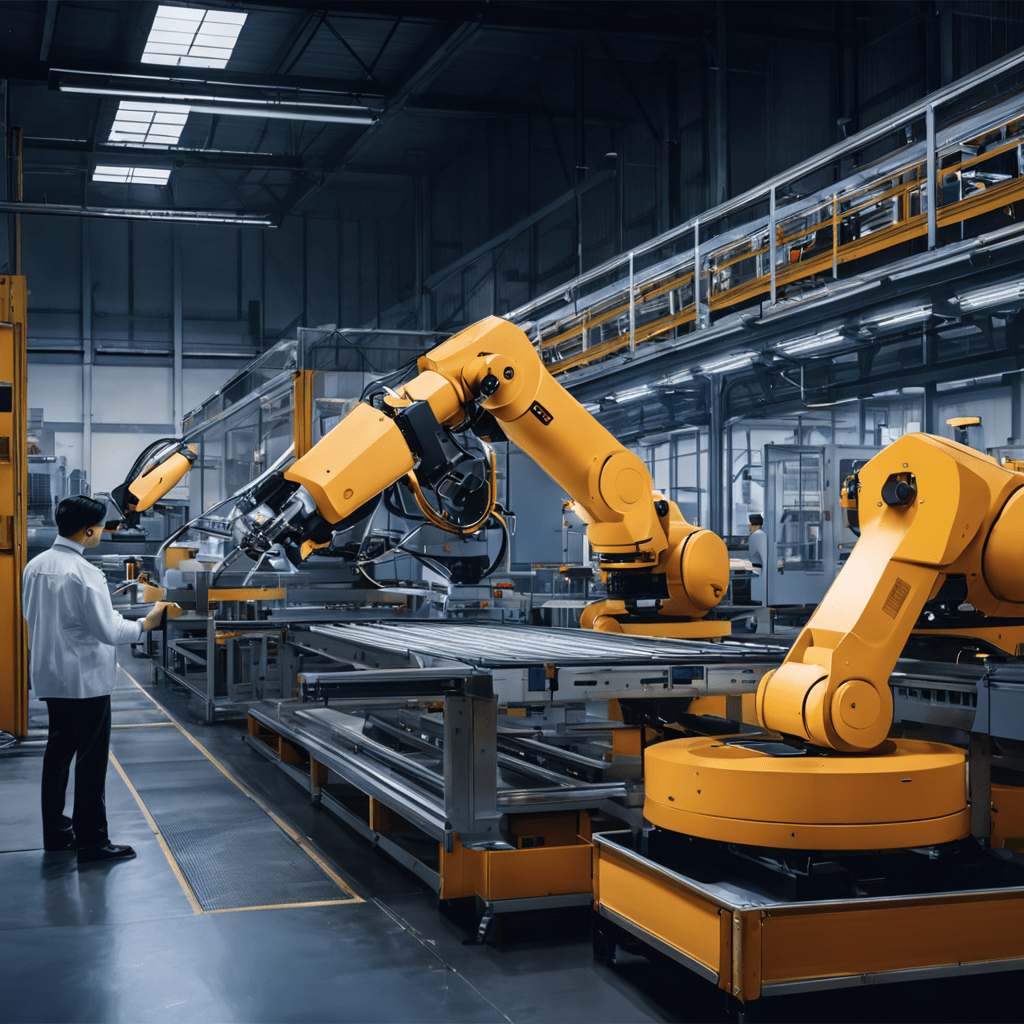

However, pondering about these manufacturing workers diverted my thoughts in a different direction. I ended up thinking about the impact of manufacturing automation on human workers, and then my thoughts drifted into the automated manufacturing lines that most large automakers tout and flaunt.

The connecting link for me was that since most of the manual tasks are handled by robots, the workers left on the floors must have a skill set higher than their previous generations. If that is the case, the increased skills requirement should be reflected in salaries. If that is not the case, maybe we still have not optimized how we automate manufacturing and warehousing?

But keeping that debate aside, we know that every investment in automation comes with increased productivity. That is how business cases are made. But what exactly defines productivity for defining these business cases? Are you producing more with the same resources? Producing more with fewer resources?

This two-part article will first overview a high-level framework to start thinking about the automation strategy. Then, in the second part, I will highlight issues with the current approach to developing these business cases and how this framework can help build a better business case, which will lead to investment in optimal types of bots.

Business leaders must develop a Manufacturing 4.0 robotics strategy to start building their capabilities and prep their Manufacturing infrastructure for the Factory of the future. It is critical to be positioned prudently once the technology moves from emerging to maturity.

But that process can’t be haphazard, trying to replicate what others are doing. A few high-level points that you need to keep in mind are:

- The deployment must be planned, orderly, and rationalized

- Workforce and Manufacturing leadership has been educated and trained on these technologies

- Policies and guidelines have been created that will standardize applications, technologies, and supplier requirements

In a nutshell, it is critical to think about planning your Manufacturing 4.0 robotics as a strategic exercise that aligns with your organization’s manufacturing and corporate strategy.

A Suggested Approach

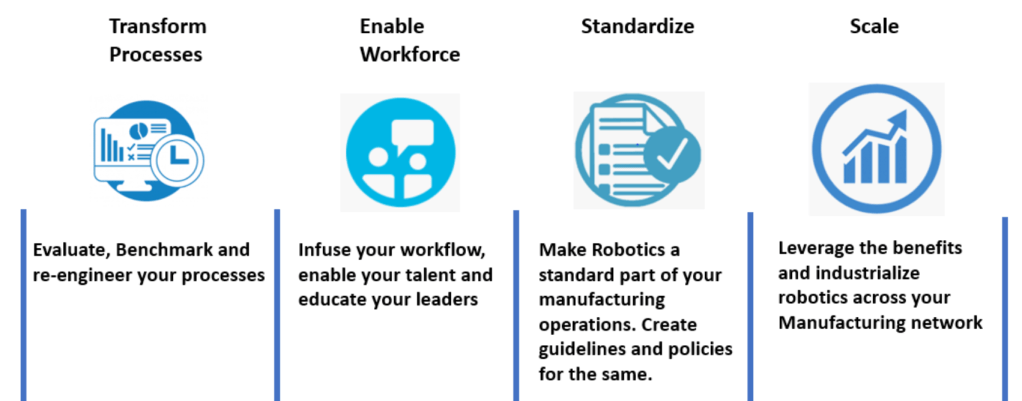

The proposed approach to develop and execute the Manufacturing Robotics strategy is shown in Figure 1. This path will help you leverage robotics as a core competency in your manufacturing strategy, in a way that is better aligned with your unique needs.

Now, we will review these four steps at a high level to understand what each of these entails.

Process Transformation

The high-level question you are looking to answer in this stage is :

What areas in your Manufacturing operations are good first candidates, and what needs to be done to prep those areas?

This step also outlines subsequent steps and best practices to ensure a harmonious and accelerated deployment, along with selecting the type of technology that can be best leveraged for the established processes

When choosing the proper process, some criteria that you can use are:

- Labor Intensity

- Skill set shortage

- Too intense for manual work

- Hazardous operations

- Critical operations

- A significant reduction in total time can be achieved

- Significant improvement in Quality

Workforce Enablement

Technology is efficient only when your workforce has the skill to leverage the technology best. A mindset change is needed from the manufacturing floor to the C-Suite. Developing specialized Robotics and automation training and linking it to career development by making it an integral part of performance assessment is critical. Collaborate closely with universities and other research centers in the Industry 4.0 domain.

Standardization

As the Manufacturing environment changes, the policies must also adapt to provide new mechanisms for improving operational efficiency. Example can be:

- Companies must develop inclusive validation processes to take into account autonomous robots

- Develop safety procedures for collaborative robots

- Develop guidelines to expedite the analysis of robotics applications

- Develop robot risk analysis aligned with international standards

Scaling & Industrialization

No strategy is of value if not implemented efficiently and effectively. To significantly impact the correct scale, a team must promote collaboration and good practices and incentivize implementation across the organization.

You need to create a team that will be accountable for Manufacturing 4.0 deployment and will aid with the following:

- Build the business case to win support and gain buy-in through quick wins that can deliver early benefits, which in turn can fund a broader program

- Create a Center of Excellence (CoE) as a means to scale up robotic implementation and promote policies in alignment with the vision of the organization and its strategic imperatives

- Develop the Robotics Technology roadmap for the next five to ten years

In the second part of this article, we will explore why productivity is not the optimal metric for robotics evaluation and how the framework above can be applied to preparing a strategy. The second part of this article can be found here.