All strategic initiatives in the world of business should have a purpose. Some are intended to decrease cost; others aim to increase revenue and/or capture more market share. The argument holds for establishing internal supply chain analytics capabilities as well. You need to carefully define some aspects before you start establishing a team.

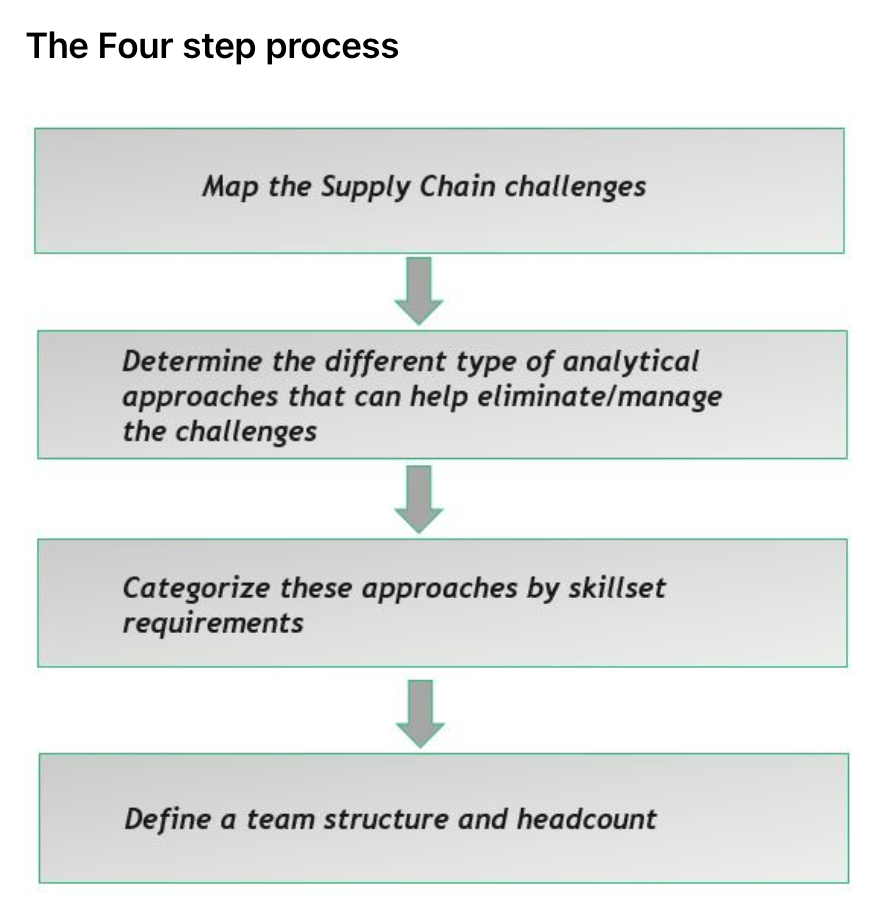

So how exactly do you find that purpose- the factors that propel the need for an internal analytics team focused on the supply chain? This article suggests a four-step process that you can leverage to bring more science into your supply chain hiring.

At a very high level, this journey generally starts with corporate strategy. However, this article assumes that all those high-level strategies (corporate, operations, etc.) have already been defined. Your supply chain strategy is already aligned with your corporate strategy.

Given all this-why, do you need an internal analytics team? It’s simple- your supply chain is a collection of processes with kinks and issues, like every other real-world process. You want to establish a scientific approach to tackle these challenges. You want to have a proactive approach to managing your supply chain. You want to provide your operations team with facts, figures, and recommendations to help them run a world-class supply chain.

And to do all that, you need to get a good handle on your analytics requirements since it forms the foundation of building a supply chain analytics team.

What tools can be used to capture analytics requirements?

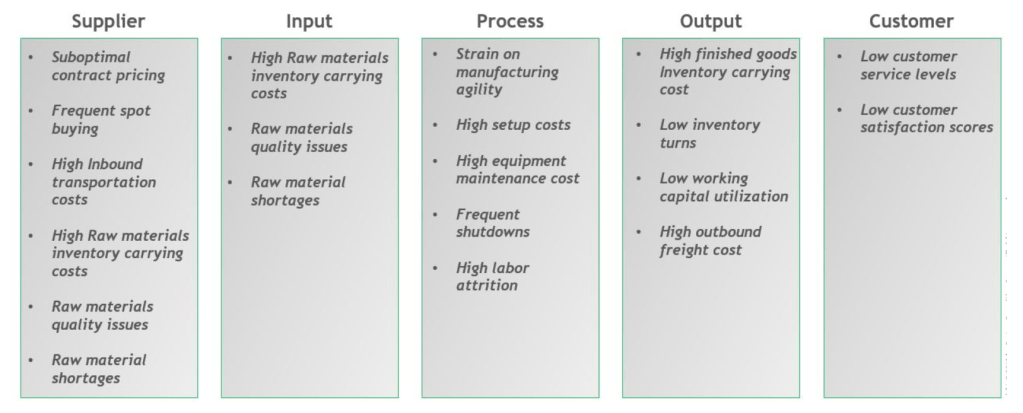

The key aspect here is that you need to map your supply chain process in enough detail to map the challenges at a high level. The process view of the supply chain is very useful for this exercise. You can use any tool of your choice-the tool I find most useful is a tool frequently used in Six Sigma, termed SIPOC.

A SIPOC diagram is a form of process mapping. Process mapping is a term used to describe the task of putting a project’s goals and, in some cases, detailed steps on how those goals will be accomplished. It’s a simple but effective method for ensuring every project team member and executive leadership is on the same page.

It also offers an overview of a project at a glance. In the case of SIPOC, the resulting diagram provides a high-level process map, the sort used by leadership to quickly explain a project and provide common reference points for all team members. It also can help identify problems and isolate areas that are not needed or add little value.

Elements of SIPOC

So, what do the five areas of the diagram include? Here are short explanations.

- Supplier – The provider of inputs into a process

- Input – Materials, information, and other resources needed to complete a process

- Process – Structured steps used to convert inputs into outputs

- Outputs – Products or services resulting from the process

- Customer – Recipient of the outputs

Mapping SIPOC Elements to a Supply Chain

Use SIPOC to map your key challenges.

Let us use an example for a CPG company to understand the process. If you were to capture some of the key challenges for each of the SIPOC process elements described above, the resulting SIPOC diagram would look like this:

Determining the Analytical approaches

Based on the challenges/problems defined, we determine the analytical approaches needed across our supply chain. The analytical approach requirement is shown below.

Skillsets requirement generation

Now that we know what the different types of analytical approaches are the team will be working on, we need to determine what type of Analytics skill set corresponds with these Analytical approaches. A few examples of the process of skill set determination are shown below:

These skill sets should form the foundation of every design aspect of your team, structure, hierarchy, headcount, stakeholder interfaces etc.