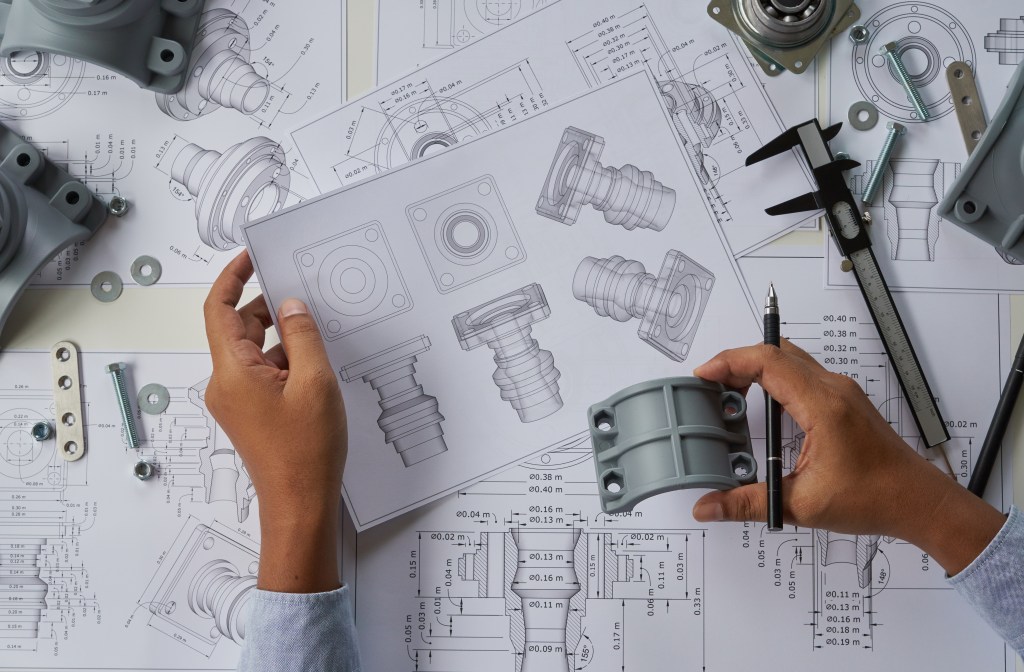

Product design can have a significant influence on supply chain efficiency. To begin with, let us quickly overview the challenges product design can introduce in the supply chain.

Time to Market and Time to Scale: Design decisions on the functionalities of the product can:

- Increase manufacturing complexity

- Decrease flexibility and responsiveness

Impact on Manufacturing: Product design can significantly impact manufacturability in the following areas:

- Manufacturing costs

- Quality failures

- Manufacturing lead times

Warehousing and Transportation: The form factor (physical specifications) of product design impacts warehousing and transportation in the following areas:

- Packaging cost

- Storage cost

- Transportation cost

Inventory: Low level of commonality in product designs in a product portfolio increases complexity, adversely impacting inventory holding costs.

Procurement: Low level of commonality in product design also means fewer chances of economies of scale; thereby, we end up losing procurement benefits that we can derive from economies of scale.

Increased Order Fulfillment Time: Non-optimal product designs add complexity to the Bill of Materials (BOM) and send procurement professionals on a hunt for specialized suppliers; many of these specialized suppliers are generally offshore. Increased Inbound transportation lead time can negatively impact the total order fulfillment time.

Supply Chain risks: As mentioned above, complexities in product design can influence supplier selections and may lead to a geographically distributed global supplier landscape. This adds significantly to supply chain disruption risks and control.

Sustainability: This will soon become a significant objective in vision and mission statements. Sustainable product design will quickly become a requirement. Most products designed today are not created from a sustainability perspective, leaving an adverse environmental impact during and towards the end of their life.

Late Stage customization: Non-optimal product design can significantly hinder the ability to postpone a product’s final configuration or packaging and will therefore increase the fulfillment lead time.

Aftersales: Product design will impact after-sales parts inventory, which increases exponentially with the complexity of the product design.

Incorporating analytics to incorporate supply chain impact

In the age where we claim to be able to build digital models of physical products, it is not difficult to quantify all the product design parameters. It is already done at some levels in a few industries. Product design initially starts with the goal of fulfilling a need. And that should always be the starting point.

And then, the optimization of the design kicks in. Within the parameters or constraints that the product will enhance customer experience, how can you optimize design parameters to minimize supply chain challenges? For many products, this can be modeled by leveraging analytics very precisely.

And this does not always apply to products with complicated designs. A version of this form of analytics can be extrapolated to CPG. Companies with hundreds or thousands of SKUs can leverage AI to understand the impact of form factors of packaging on supply chains while fulfilling consumer needs.

A decade ago, incorporating supply chain challenges was not the primary goal when strategizing product design. Except for some industries, it is increasingly imperative that supply chain aspects be included in product design. And AI can help do that very effectively.