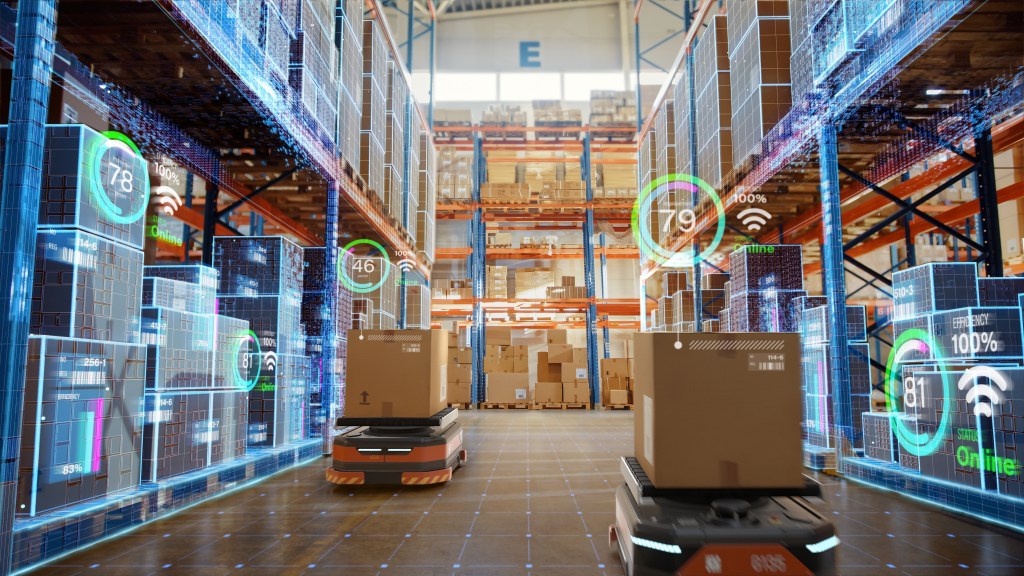

The jargon AIoT came into existence because AI and the Internet of Things (IoT) are powerful tools, when paired together, can help build innovative and enhanced capabilities. In the context of warehousing and logistics, AIoT can help enable warehouse and distribution centers to address today’s rapidly shifting supply chain dynamics.

Despite the emergence of the term AIoT, AI and IoT are frequently used in silos, in many warehouse operations & warehouse planning scenarios. This leads to missed opportunities in value realization.

Now AIoT generally pertains to devices on the edge that can perform some level of AI-enabled analytics on the edge device itself. But as I have mentioned in my posts, jargons often constrain our thought process. Jargons are not laws of physics so we can extrapolate the combination of AI and IoT, i.e AIoT, beyond edge devices.

Remember that many fundamental problems you try to solve in the warehouses have not changed dramatically for years. It is just that the combination of AI and IoT can help you build solution approaches that did not exist before. While IoT helps you capture data that could not be charged back, AI analyzes micro-decisions and optimizes them to a previously impossible level.

Smart or automated?

In 2019, I wrote an article on my blog, “Is your DC smart?” The article explained, with an example, the difference between a smart warehouse and an automated warehouse. This was before the terminology AIoT had proliferated. The example in my article suggested coupling the powerful capabilities of AI and IoT. In my opinion, implementing only IoT, without AI capabilities, allow you to capture only a tiny percentage of actual benefits in the warehouse.

As many Supply Chains shift towards being Demand-driven and as we start discussing “lot size one” in manufacturing, now is the time to leverage technologies to accommodate the current shift from forecast-driven to demand-driven DCs. But are our current Warehouse systems equipped to handle this shift?

Among many bottlenecks that warehouses will face on their path to align with Industry 4.0 initiatives, WMS is a prominent one. Most WMSs are designed to support decisions that are made with rigid decision parameters. But the fact is that increasingly evolving business landscape, nothing is static. Rigidly configured presets are increasingly becoming defunct. WMS applications now need to balance capacity against resources, aiming to maximize utilization intelligently.

However, a genuine, mature commercial offering in this space does not exist yet (many are in the pilot, though, including the startup I am currently advising).

Building the capability

As discussed multiple times in the article so far, the three essential steps here are :

- Build a data foundation with IoT

- Leverage value of that data with AI

- Integrating these two capabilities both at edge devices as well as within warehousing systems portfolio

Building the data foundation

Data granularity is a crucial enabler of more efficient operations. IoT data provide that level of granularity. I can confidently claim that many warehouse assets and processes where data captured by IoT can add value, may already be setup to generate and share data. You were probably unfamiliar with these locations/assets generating a treasure trove of information.

Examples? From materials handling equipment and conveyors to AVs and bots, recent versions of all these categories are capable to receive and send data. And so do mobile devices like scanners and picking systems.

Organizations are investing in more data devices and actively building IoT networks in their warehouse operations. Many times, simple sensors provide information not previously available for decision-making. Smartphones are part of that new network.

Building out AI Capabilities

If you have worked effectively on building the foundational aspect of capturing data effectively, access to data will become easier. The key then is to explore and exploit how to generate value from the data. That’s where AI enters.

AI solutions in your warehouse can learns and react to the current state, not to a predefined set of rules. AI and IoT, while two different technologies, have a solid and effective symbiotic relationship. More data you capture, more an AI algorithm can learn. Let us review an example.

Example:

A control tower receives data from temperature sensor on a perishables truck, that indicates spoilage due to temperature issues (AIoT on the edge). An replacement load is dispatched but it is definitely going to arrive late.

The control tower informs DC operations about an inbound that will be arriving late. An AI algorithm uses that input and determines the optimal schedule, dock and labor deployment to unload the inbound load. The algorithm can do that in real-time, as it received the inputs. It pairs the information from the control tower with IoT data collected from docks and assets (forklifts), worker tags and interfacing applications. AI can also help with allocation optimization of the inbound (what portion of that load should go directly to fill orders vs storage).

This is just one example. With the advent of Generative AI, you have the opportunity to quickly and efficiently build such a setup and harness the true value of AIoT capabilities.