There is nothing fancy about IoT-enabled manufacturing systems in 2023. Many organizations have either already embarked on this journey or have set up manufacturing systems enabled by IoT. But the key to remember is that at the end of the day, that setup is essentially hardware coupled with automation, data capturing, and processing systems.

While the system provides automation and visibility that did not exist before, it is not the differentiator. Remember that a differentiating capability cannot be bought off the shelf. In this article, we will discuss how analytics can help build those differentiating capabilities.

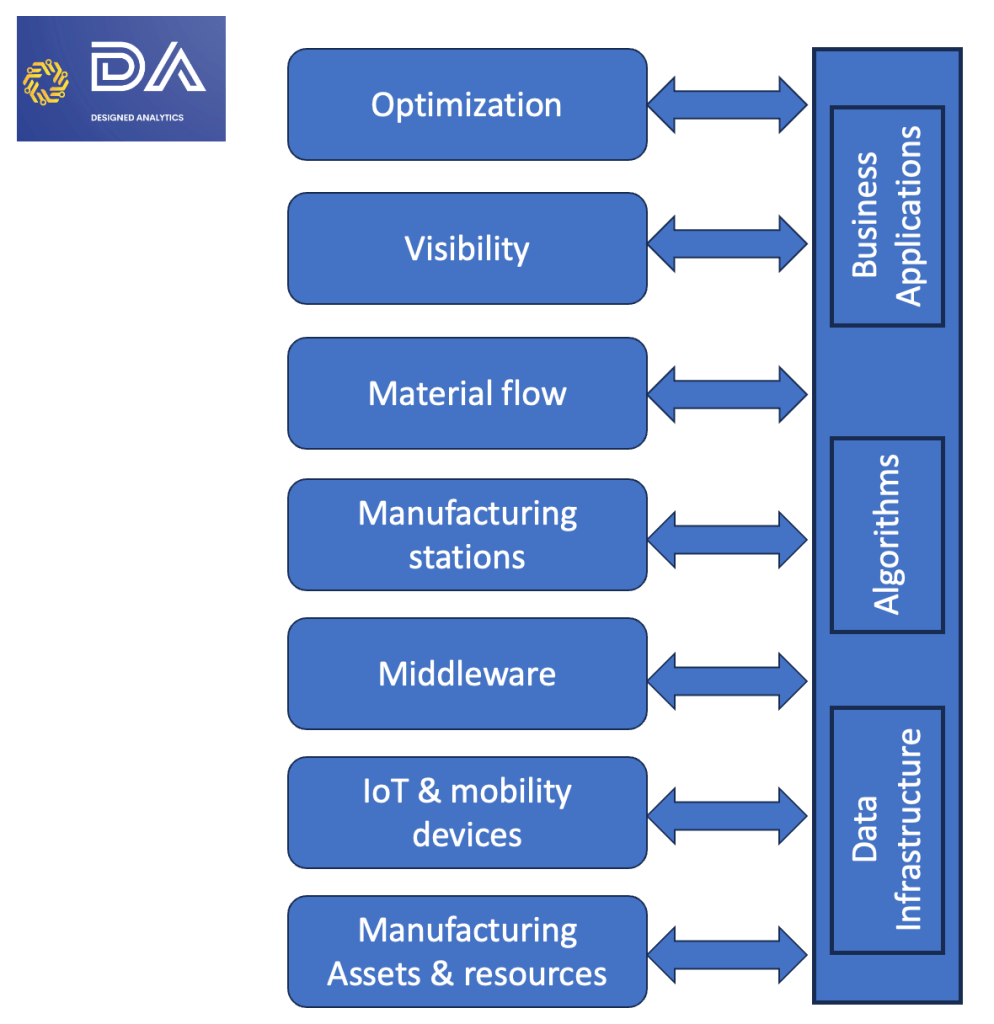

Let us review the high-level architectural components of a high-level IoT-enabled manufacturing system.

At this level, as you can see, you can buy every component of it or the solution as a whole. So can everyone else. It is essentially readily available hardware, software, and edge devices. You should get this setup as soon as possible to avoid lagging in your digital journey. This also helps you build a foundation. But this is what all your competitors can easily replicate.

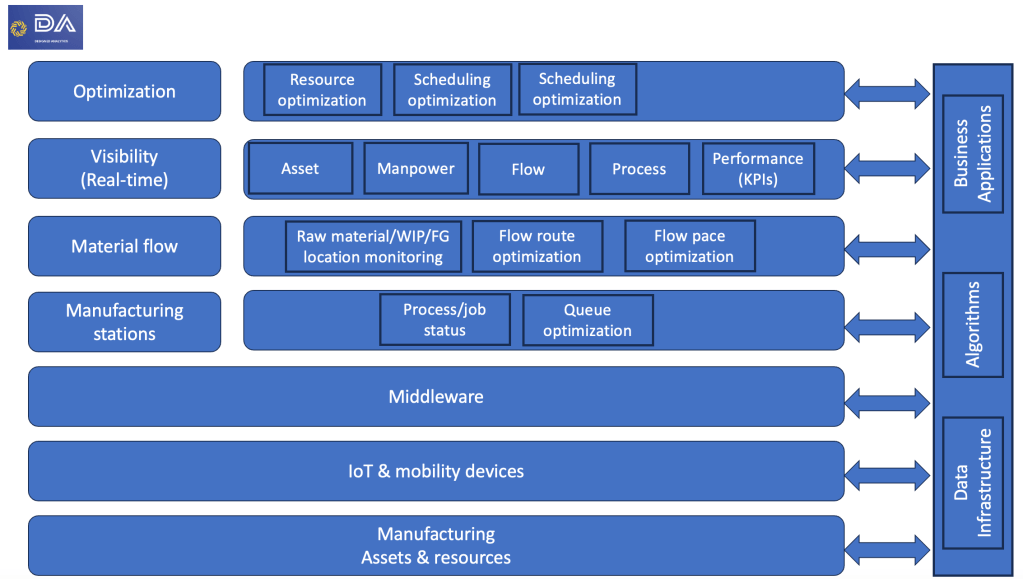

Now take a look at this more detailed architecture. We will leverage this to highlight where differentiation opportunities lie.

Manufacturing station layer

The first layer where you can start building differentiating capabilities, is smart station. The key components here are:

- Real-time production guidance

- Real-time production requeuing

As you can assume, classic optimization models will not work for either of the two segments. And the reason is embedded in the term “real-time.” As I have highlighted in articles like this, tactical use of optimization models is challenging, specifically in real-time scenarios. And this is where you can leverage deep learning. An example of real-time production sequencing using deep learning can be found in this article.

Material flow layer

Let us look at the next layer of Material flow layer. The differentiating component in this layer is:

- Real-time flow optimization

As highlighted in this article, deep learning can help optimize flows in manufacturing and warehousing scenarios. In a manufacturing setup, I see these deep learning models being trained on the simulation model’s output data.

Visibility layer

The component where you can build differentiating capability is:

- Real-time performance management

Manufacturing solutions already have performance management capabilities embedded. But you can define your KPIs if all the data points are captured and available in real time. While manufacturing has used certain standard KPIs for decades, we now have the opportunity (and capability) to define and track granular KPIs.

Optimization layer

This is the layer where almost all the components can help build differentiating capabilities. Examples are:

- Manufacturing resource assignment

- Manufacturing task scheduling

- Production scheduling

Since real-time may not be the absolute requirement for these, optimization algorithms can be used. Developing heuristics is an approach that can handle your unique nuances. Unless your processes are too convoluted, most planning solutions and modules within ERRP can be levered to run an initial optimization. You can use this output for a “refinement” algorithm that applies your custom constraints.

Conclusion

Technologies like neural networks have existed for almost half a century now and their applications explored in thousands of research papers. The good news is that we are in an era where you have everything you need to build the differentiating capabilities identified in this article.