Energy is a critical resource for countries. As we know, wars are fought to preserve energy sources like oil. So it is not surprising that maintaining the infrastructure for energy production is critical. The oil and gas industry has leveraged sensors and data captured through these to keep track of their infrastructure for a while. Much before Industry 4.0 became the hype it is now.

That means oil and gas have experience leveraging that data for operational efficiency. Many of the advanced analytics approaches that have been developed in oil and gas can be repurposed to address other business challenges. In this article, we will use the example of leveraging analytics to predict slugging in gas lift wells. We will review an example of how that approach can be repurposed to address business challenges in other industries.

Forecasting slugging in gas lift wells [1]

Oil wells have a lifespan like all other machinery and industrial assets. Slugging is a challenge that almost every oil well will face during its lifetime. Sometimes, it may be severe enough to use the well only intermittently or shut it down entirely. Various underlying causes can induce slugging. Examples are riser, pigging, hydrodynamic, and terrain slugging. For our example, we will use terrain slugging

As you can imagine, slugging impacts the flow of the liquid. It leads to intermittent flow and causes production challenges. Oil and gas have mastered the art of modeling the slug flow physically through simulation models. However, the predictive capability of these models is still mediocre. Peter Barges, in his book “Machine Learning and data science in the Oil and gas industry,” highlights:

“These purely physical models need constant tuning and adjustment. Moreover, slug frequencies are often very short, but a calculation cycle is performance intensive and takes time. Although the model might be well maintained, and the performance is good, the predictability is often mediocre.

Seeing the value generated by mitigating slugging and guaranteeing stable flow makes the problem especially important to solve. Understanding the restrictions and downsides of a purely physical model approach, such as its tuning and maintenance time, the value of trying a data-driven approach became attractive.”

Peter then suggests an LSTM model to help forecast slug flow behavior, in near real-time. To quote Peter again:

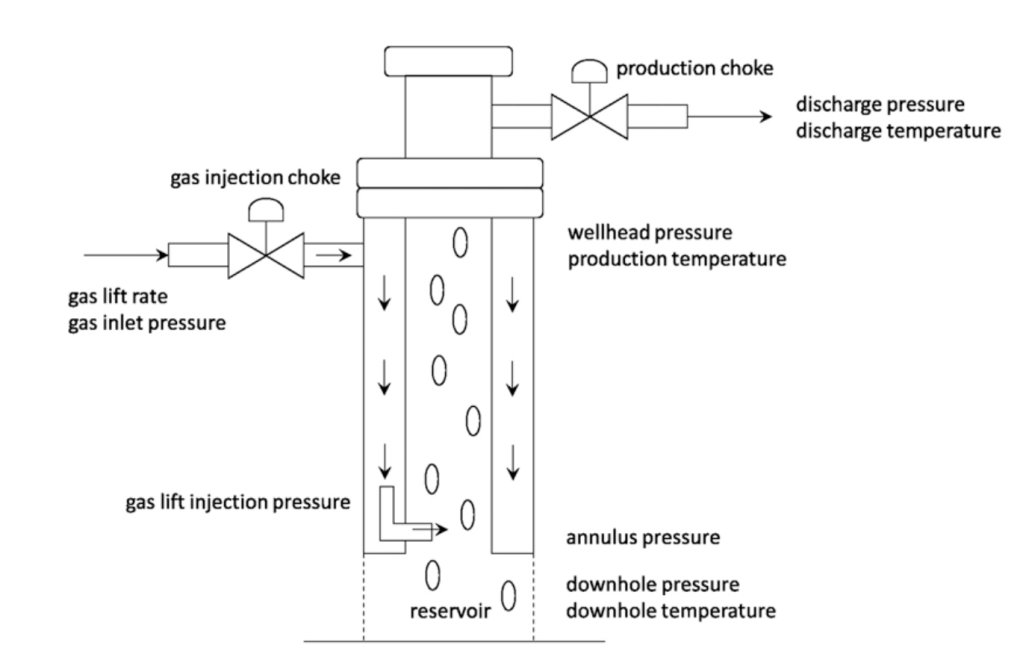

“An LSTM ingests and forecasts not just one variable but multiple ones. For our purposes, all the quantities measured and indicated in Fig. were provided, including the production choke setting. The model therefore forecasts the slugging behavior relative to the other variables. As the production choke setting is a variable under our influence, we may ask whether we can mitigate the upcoming slug by changing the choke. The model can answer this question.”

The figure in Peter’s quote is below.

Source: Machine learning and data science in oil and gas industry, Patrick Bangert

Even if you are not familiar with the LSTM approach, you should be able to follow the use case since no technical jargon will be used.

Extrapolating the solution

At the core of the slugging use case is flow. Cut all the function, sector, and industry-specific noise from the problem statement. Once you look at it from this perspective, you can start thinking about possible use cases of this approach:

- There is a flow that needs to be flowing within a specific desirable rate

- Some variables interact with the flow

- Changes in some of these variables can impact the flow

With that perspective, if you look at the diagram above, one use case becomes readily apparent- traffic flow management. As I was looking at the chart, the pipeline in the graph can be a one-way highway/road that sees a high volume of traffic flow.

So I started digging to understand if my theory that LSTM can be leveraged for traffic flow management holds. And it looks like it does. I found a few research papers exploring LSTM for traffic flow management [2]-[4], and if you go through some of them, you will be amazed at how you can frame the traffic flow problem very similar to the flow problem in the slugging use case.

That is the beauty of algorithms. If you can build intuition in applying these algorithms, you will automatically see opportunities to leverage them in the real world.

Returning to possible use cases, let us get back to the core flow problem. Remember that flow doesn’t always need to be the flow of physical objects. An example is the flow of data as transactions get executed. But for now, let us focus on the flow of material things to constrain this discussion to the supply chain.

Material flows in the supply chain world

Supply chains are all about the flow of materials. But let us talk about flows within four walls that we have focused on taming with analytics. Just like the slugging problem, simulation models exist to help predict flow issues in high-volume, high-SKU count warehouses.

And whether we want to accept it or not, just like the simulation models for slugging, they have not been that great in forecasting. Most such models wither and fade away in oblivion after sometime-till another consultant shows up promising Nirvana.

And like the slugging use case, LSTM models can also be beneficial in this context. This model can forecast possible bottlenecks to your warehouse flows and help you in sales and planning execution (S&OE).

But a key point to note here is that it has to be a large volume, high SKU count operation. LSTMs perform well when the data volume is enormous. Otherwise, the results may not significantly differ from your existing simulation models.

There is also a workaround to try LSTM or similar models. As this article suggests, you can generate massive data using thousands of simulation runs and leverage that for training and learning your neural network.

Even when you decide to replace simulation models with LSTM, it is not a straightforward deployment to production. Deploying these models beyond pilots requires that you factor in many critical aspects, like the state of existing warehousing systems. But the good news is, it can be done.

References:

- [1] Book: Machine learning and data science in oil and gas industry, Patrick Bangert

- [2] Research paper: A Deep Learning Framework About Traffic Flow Forecasting for Urban Traffic Emission Monitoring System, Yao et al

- [3] Research paper: A hybrid deep learning approach with GCN and LSTM for traffic flow prediction, Chen et al

- [4] Research paper: Modelling a signal controlled traffic stream using cellular automata, Rakha