The critical role of time standards in Warehouse operations

A warehouse manager can use time standards in various applications and virtually any working environment. Some of these applications are explained below:

- Estimating Labor requirements

- Scheduling jobs and workflows

- Providing measures of productivity

- Evaluating alternating options

- Improving warehouse operations

- Providing real-time values for simulation analysis

- Benchmarking against Industry standards

Time Standard Techniques

There are generally four widely used techniques for developing time standards, but I have used the following two in my Algorithm setup:

Time Study: Most widely used. Times are determined from the actual stopwatch timing of an operation. A stopwatch time standard is established by breaking down the processes into small, readily timed elements.

Predetermined time standards: A collection of ready-made time values for essential motion elements. This includes predetermined motion time systems (PMTS), initially developed by experienced analysts who agreed on certain fundamental factors, concepts, and constraints underlying their systems. Some examples are:

- Methods of time measurement (MTM)

- Work factor system (WFS)

- Dimensional motion times (DMT)

Developing initial time standards is a manual process if done via Time study. For our architecture, we will assume that we already have determined what the

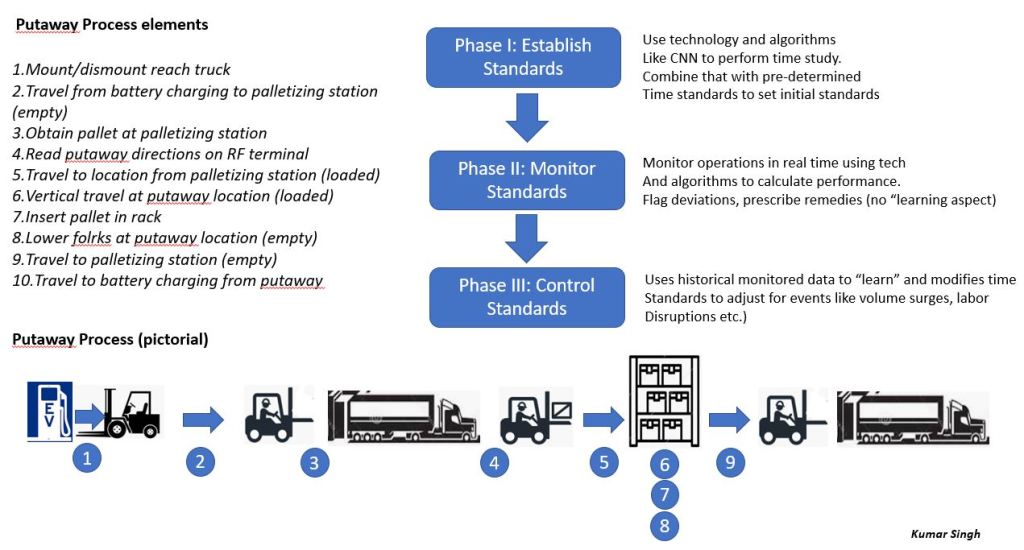

Our example process – Putaway

Explaining the architecture for end-to-end Warehouse operations is much beyond this article’s scope, so that we will use just one process as an example. The process we will use for our model is the putaway process. Here are the critical elements of a pallet putaway process:

- Mount/dismount reach truck

- Travel from battery charging to the palletizing station (empty)

- Obtain pallets at palletizing station

- Read putaway directions on the RF terminal

- Trip to the location from the palletizing station (loaded)

- Vertical travel at putaway location (loaded)

- Insert pallet in rack

- Lower forks at putaway location (empty)

- Trip to palletizing station (empty)

- Trip to battery charging from putaway (after all putaway)

High-Level three-phase flow architecture of the algorithm

Implementation and execution are the key

As with any solution, there are no cookie-cutter solutions. This architecture is suggestive and needs to be customized around your unique operations. Careful implementation is critical, which means looking beyond any pilots- and even understanding if this will be beneficial in your warehouse operations environment.