In 2018, when I started writing about AI taking over planning and decision-making beyond binary decisions, those articles were labeled futuristic. Even in 2020, I wrote an article titled “GPT-3 and the sunk cost fallacy” ( much before ChatGPT was launched and the mainstream went crazy over it )on my blog site SmartSupplyChains.ai. The gist of the article was that this tool would kill jobs and investments that may have already been made. An excerpt from that article is below:

As evident now in 2023, that is not futuristic as well.

Many AI development initiatives are now on the verge of being defunct. Generative AI premises to be a more comprehensive solution, without developing several fragmented algorithms across the supply chain or enterprise. And there is nothing futuristic about this as well.

If you want to conceptually understand how a Generative algorithm, powered by deep learning, can actually take over multiple end-to-end planning processes, you may find this article useful.

There are few aspects that you need to keep in the back of your mind as you go through this example. First is to understand the difference between an algorithm and a model. Algorithms develop models. As an example, a linear regression algorithm outputs a model, an equation, that is the representation of the relationships in underlying data. A powerful aspect of GAI algorithms will be that they can build models “on-the-go”, evolving them as the underlying data changes, and as they learn more from the data.

The second important aspect is to remember that a proper AI solution should help you make optimal real-time operations decisions. That is the most optimal (and honestly the only) way to leverage AI in a real-time operating environment. That is where deep learning comes into play. Only a deep learning algorithm can be trained to handle the gigantic data pool across the end-to-end supply chain for real-time decision-making.

Also, please remember that this is an extremely simple example to illustrate the usage. Considering the myriad state of systems in most supply chains, developing a master algorithm like this will be one of the most complex undertakings for most organizations.

Note: Though these solutions will recommend the best course, humans will still need to take the final call in most circumstances.

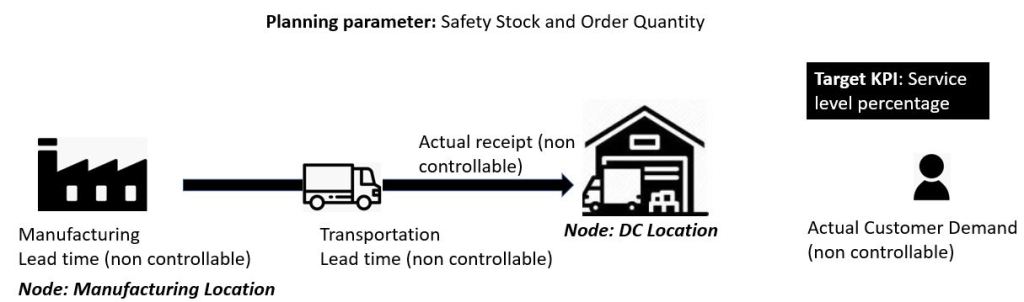

Let’s dig further into the simple example of building models that can power supply chain planning in real-time. As mentioned earlier, AI-powered supply chain planning solutions must enable you to make the best decision amid complex, highly variable processes. Such dynamic processes are everywhere in your business and involve interactions between these four key elements. The illustration below shows such an approach (inventory management).

I have used the inventory management process only to keep the example simple. In reality, the algorithm will have to encompass ALL the processes at once to capture the inter-process relationships as well effectively.

- Nodes: elements you cannot control but know in advance, like DC locations

- Input factors: elements you cannot control and don’t know in advance, such as customer demand, inventory levels, or actual receipts

- Fixed planning parameters: safety stock, planned receipts

- Variables: Inventory on hand, actual receipts

- Target KPIs: Customer service level

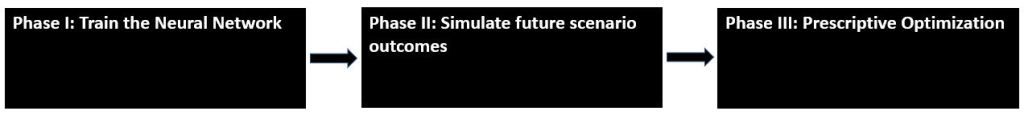

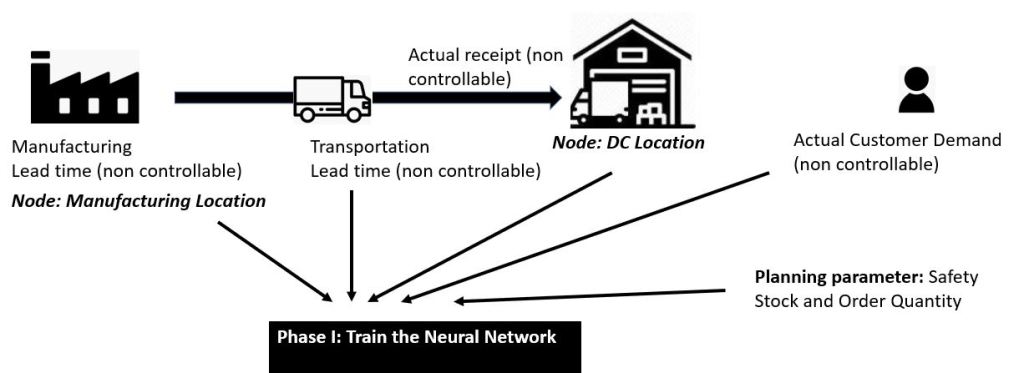

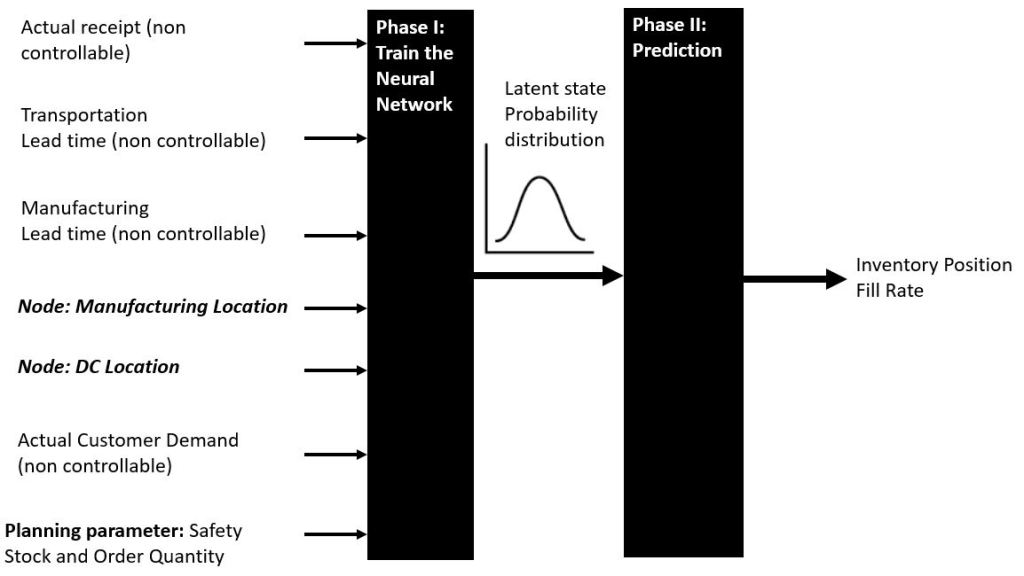

At a high level, a supply chain planning process for each planning aspect (inventory, transportation, manufacturing, etc.) will be three-phase, as shown in the illustration below:

Using algorithms that leverage neural networks, you can build deep probabilistic models of dynamic enterprise processes (basically, simulate what’s happening in your supply chain) for predictive simulations. This will allow you to optimize the decision-making policy based on those simulations. This state has two phases:

Phase 1: of the process is where given the past sequence of components like lead times, actual customer demand, manufacturing location, DC location, etc., the algorithm is trained to learn something called a latent state representation, which compresses the vast amount of historical information you have into a much smaller amount, learning only the most critical pieces of information from the data.

Beyond compressing the information, the model also maps it to a probability distribution, which is then used as part of the predictive simulation in phase 2.

Phase 2: With this latent state probability distribution, if given a set of actions and conditions across a future time horizon, you can accurately simulate measurement outcomes such as inventory positions or fill rate and target outcomes such as lost sales or value at risk. In other words, you can use the model to get an accurate simulation of the future unknowns (measurement and target outcomes), given what you

Know in advance (actions and conditions).

This part of the process utilizes the latent state representation model’s future simulation to try out different actions and select the activities that optimize your KPIs.

Given a set of known conditions and simulated unknown outcomes across a future time horizon, the optimization part of the algorithm tries out different action strategies in the simulated environment and rewards action strategies that optimize the key performance indicators associated with the desired targets. In this manner, the optimizer controller acts as a type of reinforcement learning, creating the flexibility to optimize the target outcome based on the cost considerations of your business.

Powerful together

In an enterprise with complex dynamic interactions and process variability, this model is unique in its ability to recommend the optimal actions in any scenario and continue learning based on the current activities.

The example above shows how we apply the model framework to the real world: Let’s say you’re a manufacturer interested in trying new operating strategies. Still, high costs of failure preclude you from trying anything on your factory floor. This simulation model learns to simulate future outcomes like your inventory levels (a measurement outcome) or fill rates (a target KPI), given things you know in advance, like your production schedule. Then, the optimizer tries different action strategies in the hypothetical, simulated future, assesses what would happen based on other actions you might choose, and selects the best strategy for you.

As mentioned in the beginning, a Human needs to review those strategies and use them for decision-making. While this was a simple illustration, the fact is that every technology that is required to make intelligent chains plan themselves 80% of the time now exists. The remaining 20% will anyways be long-tail, difficult to fully automate, for a long time, no matter the technological advances. Why not take that leap now and reorient your journey?