The list is simple, the journey is not

Few years from now, we will get used to products and services enabled by IoT. The fact is, many pioneer organizations already have mature capabilities in this area, but mainly in the Industrial equipment domain. For those looking to build IoT based platforms or solutions, a roadmap is a must to bring structure to the journey.

In terms of the aspects that you need to look into, or strategize about, there is a list. However, as the title of this section says, listing these aspects is easy, but undertaking the journey is difficult. Here are some criteria that can be useful for the IIoT platform and applications gap analysis:

- Completeness of the solution (edge and cloud)

- Different modes of sensing and actuation technologies, protocol support at the edge, edge analytics

- Privacy and security of the data and compliance

- Data ingestion and data storage capabilities

- Analytics and workflow capabilities

- Applications availability

- Develop an ecosystem and marketplace for services and applications

To get some perspective on the difficult part- the journey, we will use a hypothetical case study of a company that manufactures and services semi trucks, Truck Inc., to perform the roadmap analysis of building IoT platform or applications. This hypothetical case study will highlight examples of scenarios that need to be considered on the path to building IoT enabled platforms.

The following is a list of points that we will consider for our case study:

- Truck Inc. manufactures semi trucks, which cost about $250K each

- Truck Inc’s supply chain is facing the following problems:

- Growing cost concerns and complexity in managing the fleet services

- Loss of competitive footing

- Reliability and throughput issues in the factories

- Increased dependency on the supply chain system and related ecosystem

- Truck Inc’s increasing dependency arises from the following:

- Business partners such as distribution networks and repair shops share a maintenance history

- Suppliers – raw materials and parts performance

- Multiple third-party vendor tools and equipment

- Rising in-house IT costs in maintaining ERP, data warehouse, and analytics solutions with little demonstrable benefits

- Truck Inc’s executive leadership (board mandate) is keen to understand the following:

- How to maximize the operational efficiency of the fleet operations

- How to address supply-chain management

- How to prevent competition from after-market parts and services providers outside of their network

- How to address IT/OT integration issues

Since the flagship product of Truck Inc. is a semi-truck, which is a complex asset, it fits nicely with the need for an Industrial Internet platform and application. Since the company is responsible for the warranty, services, and parts, it calls for connected trucks when the trucking fleets are used at construction sites.

These connected trucks can then send the sensor, environment, and related data to the platform. The platform should provide edge connectivity to the trucks and secure communication to the platform. The need for monitoring the health of the trucks in the field and the ability to provide predictive maintenance calls for the Asset Performance Management (APM) application. This can get them started with descriptive analytics.

As part of the gap analysis, the company will have to evaluate if the analytics needed to create meaningful alarms and provide diagnostics support is provided by the APM application provider or needs to be custom developed.

Truck’s internal resources would likely have to develop predictive and prescriptive analytics. However, they need to evaluate how easily they can port their legacy analytics to this new platform. Hence, they would have to assess if the legacy analytics languages such as C/C++, Java, and .NET are supported in the evaluated new platform.

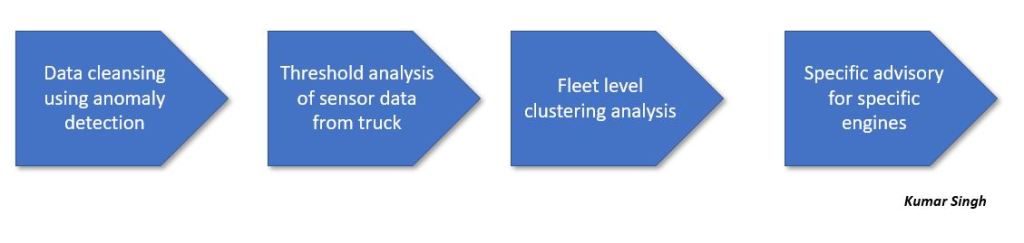

The alternative would be to rewrite these legacy analytics in newer languages such as R, Python, Java, Node.js, or Go. In addition, multiple analytics may need to be orchestrated to create the end-to-end analytics workflow. An example of such a workflow for truck data could be the one shown here:

Let’s now look at some of the elements of the platform architecture in the context of this case study. The company wants to move away from in-house IT systems to free up internal resources from routine keeping the lights on type of technology work. This leads us to examine how the Industrial Internet platform is delivered to the customer. This leads us to look at the on-premises versus cloud-based architecture.

Truck realizes that when the semi trucks are in the field operating on customer premises or the construction job sites, they are outside the corporate network. This would make the use of a public cloud-delivered platform a good option. The trucks will need wireless connectivity to the cloud platform securely. This is often achieved via a gateway device on the Truck.

The gateway device would have to be provided and secured by edge management software to allow the 12,000 trucks to be potentially connected over the next year. From an architectural standpoint, it maps to the edge and the platform tier. Since the current enterprise systems run on-premises, the platform tier on the public cloud would have to connect to the IT systems for the necessary IT/OT integration.

As we continue our analysis, we will look at the manufacturing side and the tie-in to the supply chain system. Another essential element is the field services execution and delivery applications. As the trucks are being manufactured in the company’s factories, reliability issues are leading to challenges with the throughput. This leads to challenges with the supply chain as the company cannot provide good visibility and demand forecast to the upstream suppliers. To alleviate some of these issues, the company should collect sensor data from the manufacturing assembly lines, material movement status on the shop floor, and quality data. Such capabilities are collectively referred to as intelligent manufacturing.

Next, we will focus on the gaps in providing the vital link between the manufacturing and the cementing trucks’ field operations regarding warranty and maintenance services. We noticed that the company is facing challenges in providing timely assistance to its assets, which is a threat as third parties can enter the parts and services business.

Once the trucks are connected to the Industrial Internet platform and APM applications and start providing the predictive maintenance advisories, the Truck would need a system in place for the execution and delivery of the field services. A gap that seems to jump out is field service management solutions for the service technicians out in the field and the maintenance managers. We must explore such service applications to meet this gap.